Pendant lights are a popular choice in both residential and commercial lighting projects due to their aesthetic appeal and functional versatility. As a lighting contractor, ensuring the correct installation of wall brackets for pendant lights is crucial not only for the safety and durability of the fixture but also for achieving the desired lighting effect.

Wall brackets serve as the critical support system for pendant lights, anchoring them securely to walls and allowing for proper positioning. Mistakes in selecting or installing these brackets can lead to safety hazards, damage to the fixture or wall, and compromised lighting performance. This guide aims to highlight common pitfalls and provide practical advice to help lighting contractors avoid costly errors.

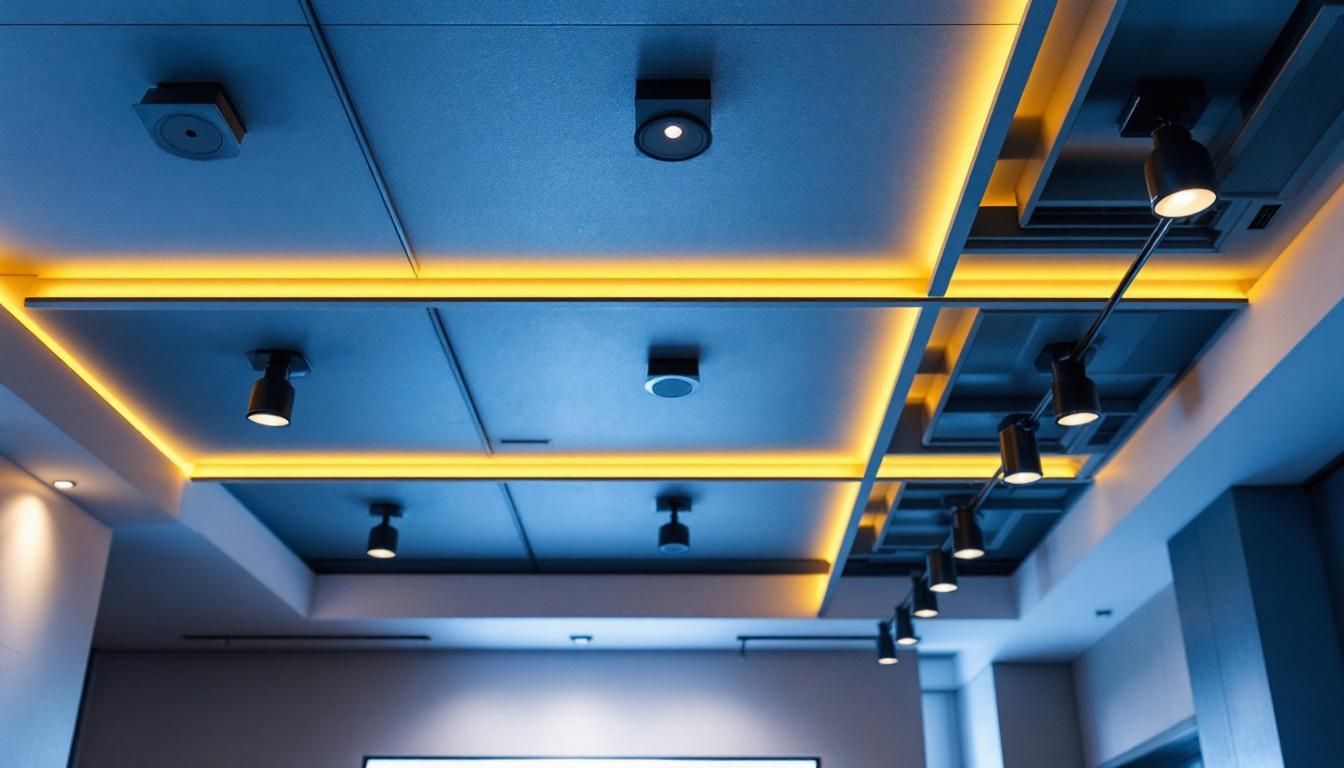

In addition to safety and functionality, the right wall bracket can significantly enhance the overall design of a space. Different styles and finishes of brackets can complement various interior design themes, from modern minimalism to rustic charm. For instance, a sleek, chrome bracket may suit a contemporary kitchen, while a wrought-iron option might be more fitting for a cozy, vintage-inspired dining area. Understanding the aesthetic implications of bracket choices can help contractors not only meet client expectations but also elevate the overall ambiance of the environment.

Moreover, the installation process itself can greatly influence the longevity and performance of pendant lights. Proper alignment and secure fastening of wall brackets ensure that the weight of the fixture is evenly distributed, reducing the risk of sagging or detachment over time. Additionally, it’s essential to consider the type of wall material when selecting brackets; for example, drywall may require different anchors compared to concrete or brick. By taking these factors into account, contractors can ensure that their installations not only look great but also stand the test of time, providing clients with peace of mind and satisfaction.

Wall brackets come in various designs and materials, each suited for different pendant light styles and installation environments. Common materials include steel, aluminum, brass, and sometimes high-strength plastics. The choice of material affects the bracket’s load-bearing capacity, corrosion resistance, and aesthetic compatibility with the fixture.

For example, stainless steel brackets are preferred in humid or outdoor environments due to their rust resistance, while brass brackets may be chosen for their decorative appeal in interior settings. Understanding the material properties and matching them with the installation context is essential for long-term reliability. Additionally, some brackets are designed with a powder-coated finish, which not only enhances their durability but also allows for a variety of color options to match or contrast with the pendant light and surrounding decor. This versatility in design can help create a cohesive look throughout a space, making the choice of wall bracket not just a functional one, but also a significant design element.

One of the most critical factors in selecting a wall bracket is its load capacity. Pendant lights can vary significantly in weight, from lightweight glass fixtures to heavy metal or multi-tiered chandeliers. Using a bracket that cannot support the weight of the pendant light risks structural failure and potential injury.

Lighting contractors should always verify the weight of the pendant light and select a bracket rated for at least 25-30% more than the actual weight to provide a safety margin. This practice aligns with industry standards and helps accommodate any unforeseen stresses or vibrations. Moreover, it’s important to consider the distribution of weight, especially for larger fixtures that may have multiple hanging points. Proper installation techniques, such as securing the bracket to wall studs rather than just drywall, can further enhance stability and ensure that the pendant light remains securely in place over time. By taking these precautions, homeowners can enjoy their lighting fixtures with peace of mind, knowing they are safely installed and able to withstand everyday use.

One of the most frequent errors is failing to assess the wall material and its ability to support the bracket and pendant light. Drywall alone cannot hold heavy fixtures without reinforcement. Contractors must identify whether the wall is drywall, concrete, brick, or plaster and use appropriate anchors or mounting hardware.

For drywall installations, toggle bolts or molly bolts are often necessary, while masonry walls require expansion anchors or sleeve anchors. Moreover, locating studs or using mounting plates to distribute the load can prevent damage and ensure a secure installation. It’s also wise to consider the weight of the pendant light itself; heavier fixtures may require additional support or a more robust mounting system. Understanding the load-bearing capacity of the wall material can prevent future issues, such as sagging or even the complete failure of the installation.

Proper placement of the wall bracket is vital for both function and aesthetics. Installing the bracket too high or too low can affect the pendant light’s illumination pattern and visual balance. Additionally, misaligned brackets can cause the pendant to hang crookedly, detracting from the overall design.

Contractors should measure carefully and use levels during installation. Consulting the lighting design plans and considering the height of the ceiling, furniture placement, and room usage will guide optimal bracket positioning. It’s also beneficial to visualize the light’s effect on the space before finalizing the installation. Using a temporary mark or even hanging the fixture with a string can help determine the best height and alignment, ensuring that the finished look is both functional and visually appealing.

Wall bracket installation often involves electrical connections, and neglecting safety protocols can have severe consequences. Ensuring that the electrical box is rated for the fixture’s weight and that wiring is correctly installed and grounded is non-negotiable.

Additionally, adherence to local electrical codes and standards, such as the National Electrical Code (NEC) in the United States, is mandatory. This includes using appropriate junction boxes, securing wiring, and avoiding overloads. Lighting contractors should always perform or supervise electrical work with certified electricians when necessary. Furthermore, it’s crucial to educate homeowners about the importance of regular maintenance checks on their lighting fixtures. Over time, wear and tear can lead to loose connections or frayed wires, which can pose significant safety risks. Keeping an eye on these aspects ensures that the installation remains safe and functional long after the initial setup.

Start by reviewing the manufacturer’s specifications for the pendant light, including weight, mounting requirements, and recommended bracket types. Selecting a bracket designed for the specific fixture ensures compatibility and reduces installation challenges.

Consider environmental factors such as moisture, temperature fluctuations, and exposure to chemicals or UV light. For example, in commercial kitchens or outdoor patios, corrosion-resistant materials and sealed brackets may be necessary.

Before mounting the bracket, inspect the wall surface for damage or irregularities. Repair any cracks, holes, or weak spots to provide a stable base. Use a stud finder or appropriate tools to locate structural supports behind the wall.

Mark the bracket’s position precisely, double-checking measurements and alignment. Pre-drill holes to prevent wall damage and facilitate easier installation of anchors or screws.

Use high-quality hardware that matches the wall type and bracket specifications. For heavy fixtures, consider using mounting plates or reinforcement brackets to distribute the load evenly.

During installation, use a spirit level to ensure the bracket is perfectly horizontal. Tighten screws or bolts securely but avoid over-tightening, which can strip threads or damage the wall. After mounting, test the bracket’s stability by applying gentle pressure before attaching the pendant light.

Over time, vibrations, temperature changes, and usage can loosen screws or anchors. Lighting contractors should advise clients to periodically inspect the wall bracket and tighten any loose components. This simple maintenance step can prevent accidents and prolong the fixture’s lifespan.

If a pendant light appears tilted or unstable, check the bracket’s mounting points and hardware. Re-aligning the bracket or replacing worn anchors often resolves these problems. In cases of wall damage, reinforcement or relocation of the bracket may be necessary.

Electrical issues such as flickering lights or intermittent power should prompt an immediate inspection of wiring connections at the bracket and fixture. Ensuring secure and code-compliant electrical installation is essential for safety and performance.

A lighting contractor installed a heavy glass pendant light in a residential kitchen using standard drywall anchors without verifying the wall’s structural support. Within weeks, the bracket loosened, causing the pendant to tilt dangerously. The issue was resolved by installing a reinforced mounting plate anchored into wall studs, demonstrating the importance of assessing wall material and load capacity.

In an outdoor restaurant setting, pendant lights were mounted using steel brackets without corrosion-resistant coatings. Over time, exposure to moisture caused rusting, compromising the brackets’ integrity. The contractor replaced them with stainless steel brackets designed for outdoor use, highlighting the need to consider environmental factors in bracket selection.

For lighting contractors, the installation of wall brackets for pendant lights is a task that demands careful attention to detail, knowledge of materials, and adherence to safety standards. Avoiding common mistakes such as improper load assessment, poor placement, and neglecting electrical codes ensures not only the durability and safety of the installation but also client satisfaction.

By following best practices and learning from real-world examples, contractors can deliver professional, reliable lighting solutions that enhance the ambiance and functionality of any space. Investing time and expertise in the correct selection and installation of wall brackets ultimately reflects the quality and reputation of the contractor’s work.

Ready to elevate your lighting installations with the highest quality brackets and pendant lights? Look no further than LumenWholesale, where we offer an extensive selection of spec-grade lighting products at unbeatable wholesale prices. Say goodbye to local distributor markups and hello to superior lighting solutions that meet rigorous industry standards. With free shipping on bulk orders, LumenWholesale is your go-to source for reliable, high-performance lighting that won’t break the bank. Discover wholesale lighting at the best value and make your next project shine with LumenWholesale.

Discover essential tips and best practices for lighting contractors when installing 120-volt LED pathway lights.

Discover how lighting contractors can revolutionize educational environments by mastering hallway lighting in schools.

Explore the transformation of dropped ceiling lights in the lighting industry, highlighting innovative designs, energy efficiency, and their impact on modern interiors.

Discover the essential resources lighting contractors rely on to master the art of illuminating parking lots with LED lights.