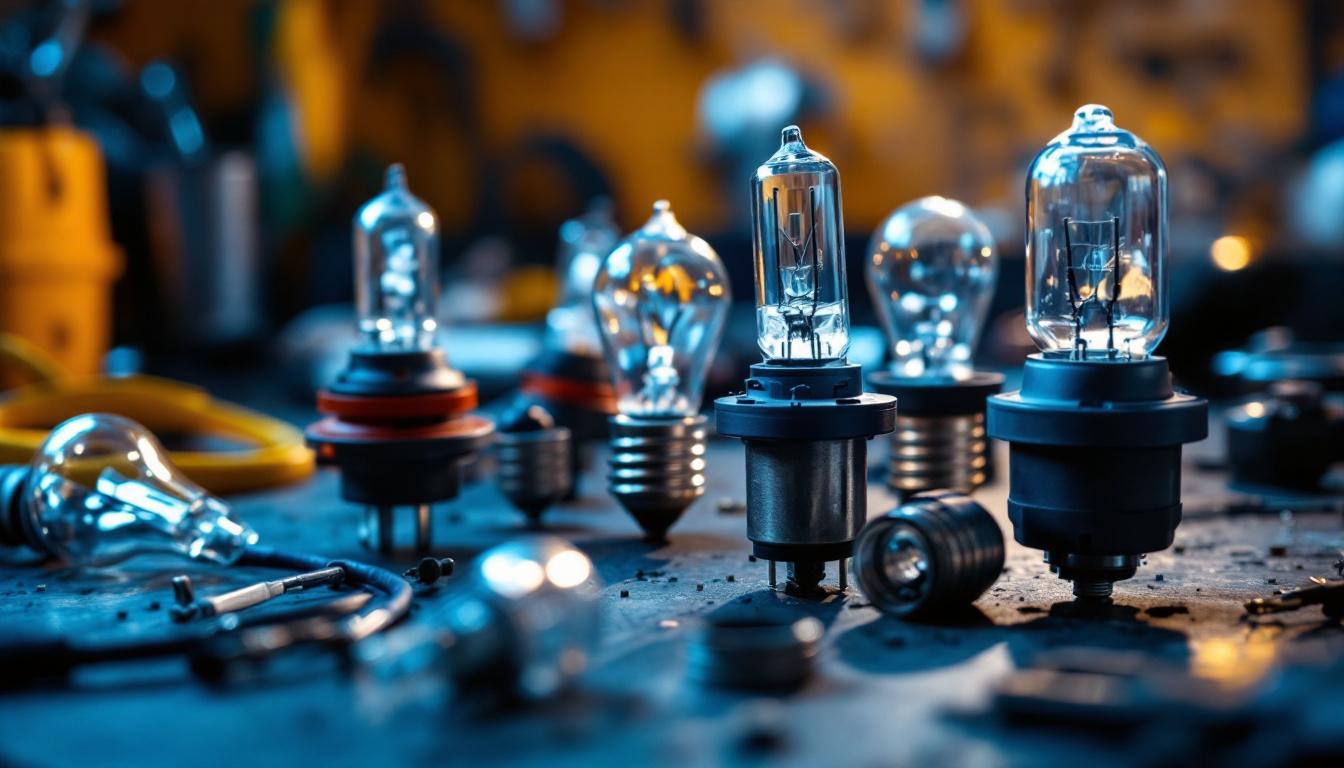

Halogen bulbs remain a popular choice in many lighting projects due to their bright, crisp light and compact size. However, the diversity of socket types can trip up even experienced contractors if not properly understood. Selecting the wrong socket not only risks installation headaches but can also lead to premature bulb failure or safety hazards.

Unlike standard incandescent bulbs that often use a simple Edison screw base, halogen bulbs come with a range of specialized sockets designed to handle their higher operating temperatures and voltages. Recognizing these differences is essential for seamless installations and client satisfaction.

Halogen sockets generally fall into several categories, each suited for specific bulb designs and applications:

Each socket type has unique physical and electrical characteristics that dictate compatibility with specific bulbs. Misidentifying these can lead to improper fit or electrical mismatches.

For instance, the GU10 socket, with its twist-and-lock mechanism, not only provides a secure connection but also ensures that the bulb can be easily replaced without the need for tools. This feature is particularly beneficial in commercial settings where lighting fixtures are frequently updated or changed. On the other hand, the G4 and GY6.35 sockets are often used in smaller fixtures, such as under-cabinet lighting or decorative lamps, where space is a premium. Their compact design allows for versatile applications, making them a favorite among designers looking to create ambient lighting without sacrificing style.

Additionally, understanding the voltage requirements of each socket type is crucial. For example, while GU10 sockets operate at mains voltage, G4 and MR16 sockets typically require a transformer to step down the voltage for safe operation. This distinction not only affects installation but also influences energy efficiency and bulb longevity. As energy costs continue to rise, selecting the appropriate socket and bulb combination can lead to significant savings over time, making it an important consideration for both residential and commercial projects.

Choosing the right socket isn’t just about physical fit. The electrical and thermal demands of halogen bulbs make socket compatibility critical for both performance and safety.

Halogen bulbs operate at higher temperatures than standard incandescent bulbs, often exceeding 250°C at the bulb surface. Sockets must be constructed from heat-resistant materials and designed to dissipate heat effectively. Using an incompatible socket can cause melting, deformation, or even electrical shorts.

Voltage and current ratings vary between socket types. For example, GU10 sockets are designed for 120V or 230V mains power, while G4 sockets handle low-voltage 12V systems. Connecting a low-voltage bulb to a mains voltage socket can destroy the bulb instantly and pose a fire hazard.

Additionally, the socket’s contact design affects electrical continuity and stability. Poor contact can lead to flickering, intermittent operation, or arcing, which accelerates socket and bulb wear.

Moreover, the quality of the socket materials plays a significant role in overall performance. High-quality sockets are often made from durable plastics or metals that can withstand high temperatures without degrading. This durability not only extends the life of the bulb but also enhances safety by minimizing the risk of electrical failures. In contrast, cheaper sockets may use inferior materials that can warp or break under heat, leading to potential hazards.

Furthermore, proper installation is crucial in ensuring that the socket functions as intended. Even the best socket can fail if not installed correctly. Ensuring that connections are tight and secure can prevent issues such as arcing or overheating. Regular maintenance checks can also help identify any wear or damage to the socket, allowing for timely replacements before problems arise. Understanding these factors can save you from costly repairs and enhance the longevity of your lighting system.

Lighting contractors often encounter several recurring issues when working with halogen bulb sockets. Awareness and proactive measures can prevent costly callbacks and safety risks.

One of the most frequent mistakes is confusing similar-looking sockets. For example, G4 and GY6.35 sockets both use bi-pin designs but differ in pin spacing. Installing a bulb with the wrong pin spacing can cause poor contact or damage pins.

Always verify the exact socket type by measuring pin spacing or consulting manufacturer specifications. When in doubt, replace the socket rather than forcing a bulb to fit. Additionally, it may be helpful to keep a reference chart of common socket types and their specifications on hand, which can streamline the identification process and reduce the likelihood of errors. This simple step can save time and prevent the frustration of returning to a job site due to a misidentified socket.

Halogen bulbs generate intense heat. Installing them in sockets or fixtures not rated for this heat can cause premature failure or fire hazards. Ensure that sockets are rated for halogen use and that fixtures provide adequate ventilation.

Using sockets made from low-temperature plastics or installing bulbs in enclosed fixtures without proper heat dissipation can degrade socket materials quickly. It’s also wise to consider the placement of the fixtures; for instance, mounting halogen lights in areas with poor airflow or near flammable materials can exacerbate heat-related issues. Implementing heat-resistant materials and ensuring that there is sufficient space around the bulb for air circulation can greatly enhance safety and longevity.

Mixing low-voltage halogen bulbs with mains voltage sockets is a common error. It’s essential to confirm the bulb voltage rating and match it with the socket and transformer setup.

For example, low-voltage MR16 bulbs require a compatible 12V transformer and corresponding socket. Installing these bulbs directly into a 120V socket will cause immediate failure. Additionally, it’s beneficial to educate clients on the importance of using the correct voltage to avoid confusion in future maintenance. Providing them with clear instructions or labeling can help ensure that they do not inadvertently replace bulbs with incompatible types, which could lead to further complications down the line. Regular checks and maintenance of the transformer can also prevent issues related to voltage discrepancies, ensuring a reliable lighting solution for years to come.

Proper installation techniques can extend the life of halogen bulbs and ensure safe operation. Lighting contractors should adopt these best practices on every job.

Always source sockets and bulbs from reputable manufacturers with clear specifications. Using OEM-approved parts reduces the risk of compatibility issues and guarantees compliance with safety standards.

Before installing bulbs, inspect sockets for damage, corrosion, or wear. Test electrical continuity and ensure secure mounting. Loose or damaged sockets can cause flickering or electrical shorts.

Halogen bulbs are sensitive to oils and dirt on the glass surface. Use gloves or a clean cloth when handling bulbs to avoid fingerprints, which can cause hot spots and shorten bulb life.

Install fixtures and sockets in a way that allows heat to dissipate. Avoid enclosing halogen bulbs in tight spaces without airflow. Consider using heat-resistant socket materials when working in confined areas.

Many clients seek to upgrade existing halogen fixtures to more energy-efficient lighting, such as LEDs. Understanding socket compatibility and retrofit options is crucial for smooth transitions.

Some LED bulbs are designed to fit directly into halogen sockets like GU10 or MR16, allowing for simple upgrades without rewiring. However, these LED replacements often require compatible transformers or drivers.

Contractors should verify that the existing transformer supports LED loads or recommend replacing it with an LED-compatible driver to avoid flickering or dimming issues.

In some cases, upgrading to LED or other lighting technologies may require replacing the socket altogether. This is especially true when moving from low-voltage halogen to mains voltage LED systems or vice versa.

Proper socket replacement ensures electrical safety and optimal performance. It’s also an opportunity to upgrade to sockets with better heat resistance or improved contact design.

Halogen lighting installations must meet electrical codes and safety standards. Lighting contractors bear responsibility for ensuring compliance and protecting end users.

Halogen bulbs’ high operating temperatures necessitate careful fixture selection and socket installation to prevent fire risks. Use sockets rated for halogen use and maintain clearances from combustible materials.

Follow local electrical codes regarding socket installation, grounding, and wiring. Improper wiring or socket installation can lead to electrical shock or fire hazards.

Halogen bulbs contain small amounts of halogen gases and should be disposed of properly according to local regulations. Educate clients on safe disposal methods or offer recycling services when possible.

For lighting contractors, understanding the nuances of halogen light bulb sockets is more than a technical detail-it’s a cornerstone of quality workmanship. Avoiding common pitfalls like socket misidentification, voltage mismatches, and poor heat management leads to safer installations and happier clients.

Staying current with manufacturer specifications, adhering to best installation practices, and planning for future upgrades will position contractors as trusted experts in halogen lighting projects. The right socket choice ensures that halogen bulbs deliver their characteristic bright, focused light reliably and safely for years to come.

Ready to ensure your halogen lighting installations are up to par with the highest standards of safety and quality? Look no further than LumenWholesale for all your lighting needs. Our extensive selection of spec-grade halogen sockets is designed to meet the rigorous demands of any project, big or small. With unbeatable wholesale prices and the convenience of free shipping on bulk orders, you can trust LumenWholesale to provide the best value without compromising on quality. Elevate your lighting projects and delight your clients with reliable, high-performance products. Wholesale Lighting at the Best Value is just a click away. Experience the LumenWholesale difference today!

Discover how transitioning to energy-efficient lighting can boost your bottom line.

Discover the top types of under cabinet lighting and how they can help lighting contractors win more bids.

Discover how 3-way switches revolutionize modern lighting solutions by offering flexibility, energy efficiency, and enhanced control in home and commercial settings.

Discover how LED fluorescent replacement tubes are transforming the lighting industry and impacting contractors’ profitability.