In the world of lighting installation, understanding the nuances of exterior electrical boxes is crucial for contractors aiming to deliver safe, efficient, and aesthetically pleasing results. These boxes serve as the foundation for outdoor lighting systems, providing protection and organization for electrical connections. This article delves into the essential aspects of exterior electrical boxes, offering insights that every lighting contractor should know.

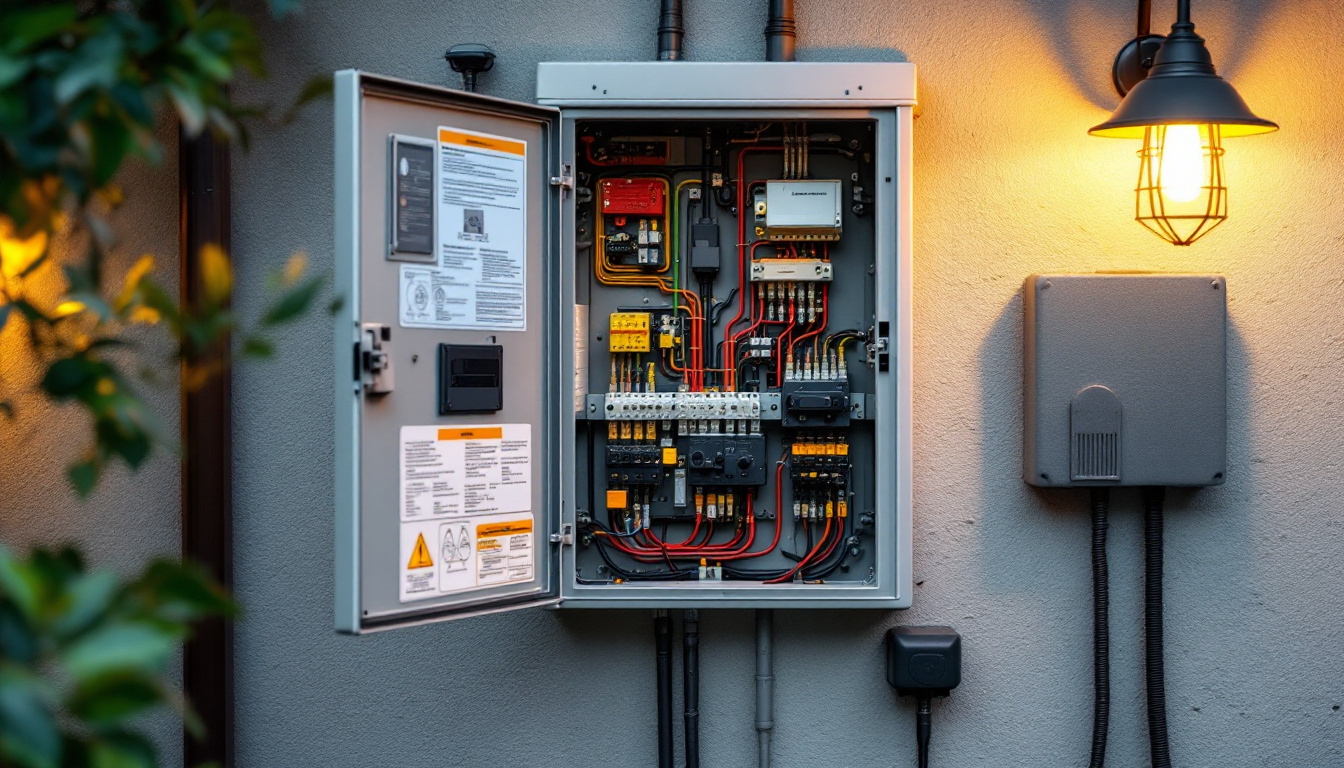

Exterior electrical boxes are designed to house electrical connections and components that are exposed to the elements. They come in various shapes, sizes, and materials, each tailored for specific applications and environments. The primary purpose of these boxes is to protect electrical connections from moisture, dirt, and physical damage, ensuring the longevity and reliability of outdoor lighting systems. These boxes play a critical role in maintaining safe and efficient electrical systems, especially in areas prone to extreme weather conditions.

In addition to their protective functions, exterior electrical boxes also facilitate easier access to electrical connections for maintenance and troubleshooting. This is particularly important for outdoor installations, where accessibility can be a challenge. Properly installed exterior electrical boxes can help prevent electrical hazards, such as short circuits or electrical fires, by ensuring that connections are secure and shielded from the elements.

There are several types of exterior electrical boxes, each suited for different applications. The most common types include:

Each type of box has its specific installation requirements and considerations, making it vital for contractors to choose the right type based on the project needs. For instance, when installing a weatherproof junction box, it is crucial to ensure that all seals are intact and that the box is mounted securely to prevent any water from seeping in. This attention to detail can make a significant difference in the performance and safety of the electrical system.

Exterior electrical boxes are commonly made from materials like plastic, fiberglass, or metal. The choice of material can significantly impact the box’s durability, resistance to corrosion, and overall performance. Understanding the environmental conditions where the box will be installed is essential for making the right choice.

Choosing the right material is crucial, as it affects not only the box’s longevity but also the safety and functionality of the electrical connections housed within. Additionally, the installation environment should be considered; for example, a box installed in a damp area may require a different material than one placed in a dry, sheltered location. Proper selection and installation can ultimately lead to a more efficient and safer electrical system.

Proper installation of exterior electrical boxes is vital to ensure safety and compliance with electrical codes. Lighting contractors must adhere to specific guidelines to avoid potential hazards and ensure the longevity of the installation.

When selecting a location for an exterior electrical box, consider factors such as accessibility, proximity to power sources, and exposure to the elements. Boxes should be mounted securely to prevent movement and damage over time.

It is essential to follow local building codes regarding the height and placement of electrical boxes. For instance, boxes should be mounted at a height that minimizes the risk of water pooling around them, and they should be placed away from high-traffic areas to reduce the chance of accidental damage.

Sealing and weatherproofing are critical steps in the installation process. All joints and openings must be sealed with appropriate materials to prevent moisture ingress. Use weatherproof gaskets and silicone sealants to ensure a tight seal around the box and any conduits or cables entering the box.

Additionally, ensure that the box is rated for outdoor use and meets the necessary standards for weather resistance. This is crucial for maintaining the integrity of the electrical connections and preventing short circuits or failures.

Compliance with electrical codes is non-negotiable in the installation of exterior electrical boxes. Various regulations govern the installation, including the National Electrical Code (NEC) and local codes that may impose additional requirements.

The NEC outlines specific guidelines for the installation of electrical boxes, including their placement, grounding, and protection from physical damage. For instance, boxes must be installed at a minimum height above ground level to prevent water ingress.

Contractors should familiarize themselves with the NEC’s requirements regarding the use of weatherproof enclosures and the types of fittings and connectors allowed for outdoor applications. Non-compliance can lead to safety hazards and costly rework.

In addition to the NEC, local building codes may impose unique requirements based on regional climate conditions and construction practices. It is essential for contractors to stay informed about these regulations to ensure all installations are compliant.

Consulting with local authorities or electrical inspectors can provide valuable insights into specific requirements that may affect the installation of exterior electrical boxes. This proactive approach can prevent potential issues during inspections and ensure a smooth project completion.

Regular maintenance and inspection of exterior electrical boxes are crucial for ensuring their continued performance and safety. Over time, exposure to the elements can lead to wear and tear, which may compromise the integrity of the electrical connections.

Contractors should recommend routine inspections of exterior electrical boxes, especially after severe weather events. During these inspections, check for signs of moisture intrusion, corrosion, or physical damage.

Inspecting the seals and gaskets for wear is also essential, as any degradation can lead to moisture ingress. If any issues are identified, prompt repairs or replacements should be made to prevent further damage.

Keeping exterior electrical boxes clean and free from debris is vital for their longevity. Regularly remove dirt, leaves, and other materials that may accumulate around the box. This not only improves aesthetics but also reduces the risk of moisture retention and pest infestations.

For metal boxes, periodic checks for rust or corrosion should be conducted. If any signs of deterioration are found, appropriate measures should be taken, such as sanding down rust spots and applying protective coatings.

In addition to the electrical box itself, various accessories play a crucial role in the overall performance and safety of outdoor lighting installations. Selecting the right accessories can enhance functionality and ensure compliance with electrical codes.

Using the correct conduits and connectors is essential for protecting electrical wiring and ensuring safe connections. Rigid or flexible conduits can be used depending on the installation requirements, with each type offering unique benefits.

Ensure that all connectors used are rated for outdoor use and compatible with the specific electrical box being installed. This attention to detail can prevent issues such as overheating or short circuits.

Proper grounding and bonding of exterior electrical boxes are critical for safety. All boxes should be grounded according to NEC requirements, which typically involves connecting the box to the grounding system of the building.

Bonding ensures that all metallic parts are electrically connected, reducing the risk of electric shock. Contractors should verify that all grounding connections are secure and compliant with local codes.

Even experienced contractors can make mistakes during the installation of exterior electrical boxes. Being aware of common pitfalls can help prevent costly errors and ensure a successful project.

One of the most significant mistakes is neglecting proper weatherproofing. Failing to seal joints and openings can lead to moisture intrusion, resulting in electrical failures and safety hazards.

Always use weatherproof gaskets and sealants, and double-check that all components are rated for outdoor use. This simple step can save time and resources in the long run.

Assuming that NEC guidelines are sufficient without considering local codes can lead to compliance issues. Local regulations may impose additional requirements that must be adhered to for a successful installation.

Contractors should take the time to research and understand local codes, ensuring that all installations meet or exceed these standards. This diligence can prevent delays and complications during inspections.

Exterior electrical boxes are a critical component of outdoor lighting installations, serving to protect electrical connections and ensure safety. By understanding the types, installation guidelines, and maintenance practices associated with these boxes, lighting contractors can enhance their expertise and deliver high-quality results.

Staying informed about electrical code compliance and best practices will not only improve the safety and reliability of installations but also foster trust and satisfaction among clients. As the demand for outdoor lighting solutions continues to grow, mastering the intricacies of exterior electrical boxes will position contractors for success in a competitive market.

Ready to elevate your outdoor lighting installations with the best in the business? Look no further than LumenWholesale for all your exterior electrical box needs. Our commitment to quality, affordability, and convenience ensures that you have access to the highest industry-standard products at wholesale prices. Say goodbye to middleman markups and hello to hassle-free bulk buying with free shipping. Don’t compromise on your lighting solutions—choose LumenWholesale for superior performance and value. Wholesale Lighting at the Best Value is just a click away. Enhance your expertise and client satisfaction today!

Discover how lighting contractors can excel in installing motion-activated flood lights with expert tips and strategies.

Discover how lighting contractors can enhance their projects with large solar post lights.

Discover how outdoor pole lights LED technology can transform your lighting projects and boost your business success.

Discover expert tips and innovative strategies for lighting contractors in “Library Lights.” Learn how to illuminate libraries effectively, balancing aesthetics and functionality to create inviting, well-lit spaces that inspire readers and enhance the library experience..