Waterproof splice connectors are essential components in the electrical industry, particularly for lighting contractors who work on outdoor installations. These connectors ensure that electrical connections remain safe and functional, even in wet or humid conditions. However, despite their importance, many contractors make common mistakes when selecting and installing these connectors.

Understanding the various types of waterproof splice connectors available and their specific applications is crucial for any lighting contractor. This knowledge not only enhances the quality of work but also ensures compliance with safety standards. Missteps in this area can lead to costly rework and potential hazards.

Waterproof splice connectors come in various forms, each designed for specific applications. Some of the most common types include heat-shrink connectors, gel-filled connectors, and crimp connectors. Heat-shrink connectors are particularly popular due to their ease of use and effectiveness in sealing out moisture. They typically require a heat source to shrink the tubing, creating a tight seal around the connection.

Gel-filled connectors, on the other hand, contain a silicone-based gel that provides a waterproof barrier. These connectors are ideal for environments where moisture is a constant concern. Crimp connectors, while not inherently waterproof, can be made so when used with appropriate sealing methods. Understanding these variations is essential for making informed decisions during installation. Additionally, some connectors are designed with built-in strain relief features, which can help prevent damage to the wires during installation and throughout the lifespan of the connection. This added durability can be a game changer in high-traffic areas or locations prone to movement and vibration.

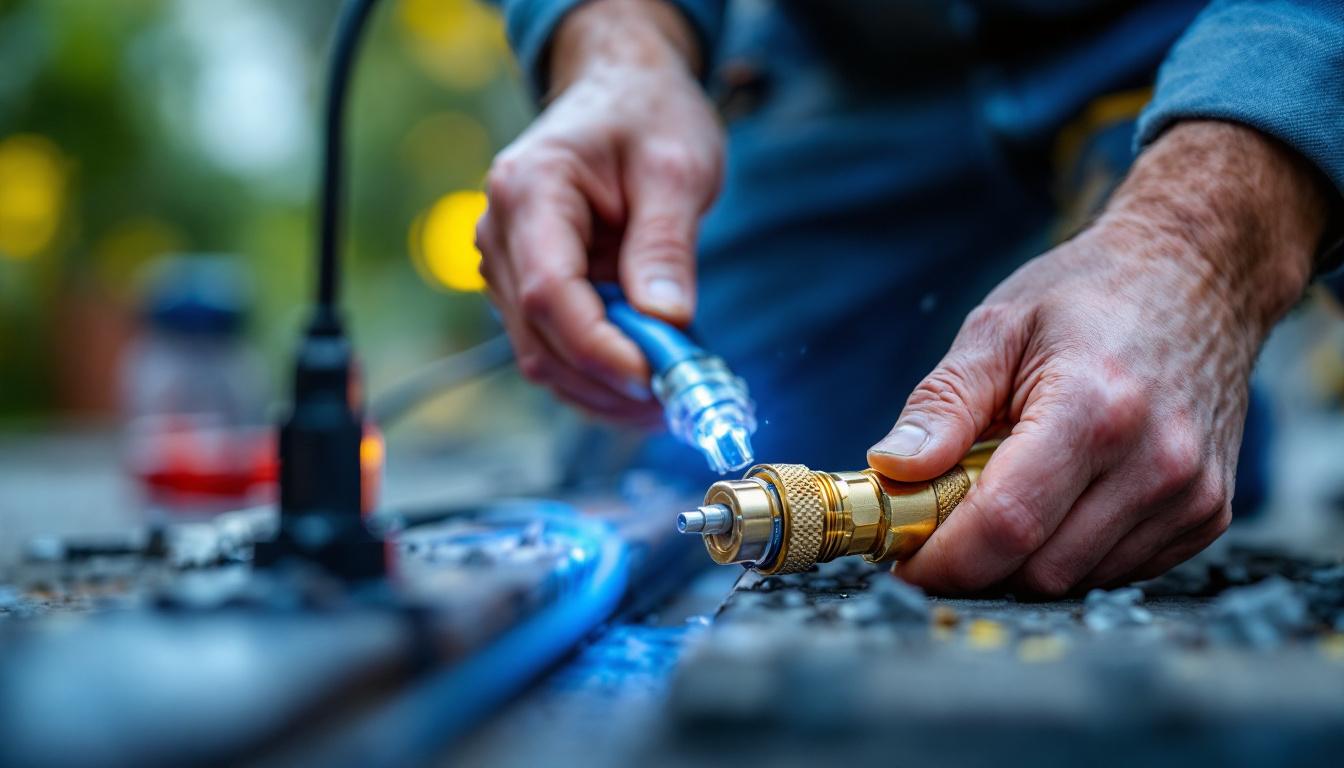

Even the best waterproof splice connectors can fail if not installed correctly. Proper installation techniques are vital to ensure that the connectors perform as intended. This includes stripping wires to the correct length, ensuring a proper crimp, and applying heat or gel as required. Neglecting these steps can lead to corrosion, electrical shorts, or even fire hazards.

Moreover, improper installation can void warranties and lead to costly repairs down the line. Therefore, lighting contractors must prioritize training and adherence to best practices when working with waterproof splice connectors. Regularly reviewing installation techniques and staying updated on industry standards can significantly enhance a contractor’s skill set. Furthermore, investing in high-quality tools specifically designed for electrical work can make a substantial difference in achieving reliable and long-lasting connections. The right tools not only simplify the installation process but also contribute to the overall safety and efficiency of outdoor electrical systems.

Despite the critical role waterproof splice connectors play in outdoor lighting projects, many contractors overlook essential aspects during their selection and installation. Identifying these common mistakes can help contractors improve their practices and deliver higher-quality work.

One of the most frequent errors made by lighting contractors is selecting the wrong type of waterproof splice connector for a specific application. Each connector type has its strengths and weaknesses, and using the wrong one can compromise the integrity of the electrical connection.

For instance, using a standard crimp connector in a high-moisture environment can lead to failure over time. Contractors should carefully assess the environmental conditions and choose connectors that are specifically designed for those conditions. This consideration can save time and resources in the long run. Additionally, understanding the specifications of connectors, such as their voltage ratings and current-carrying capacities, is crucial. Not all connectors are created equal; some are better suited for high-voltage applications, while others may be designed for lower voltage systems. By matching the connector to the specific needs of the project, contractors can ensure a more reliable and efficient installation.

Environmental factors play a significant role in the longevity and effectiveness of waterproof splice connectors. Factors such as temperature fluctuations, exposure to UV light, and the presence of chemicals can all impact the performance of these connectors. Failing to account for these elements can lead to premature connector failure.

Contractors should conduct thorough site assessments to understand the environmental conditions where the connectors will be installed. This information will guide the selection of connectors that can withstand those specific challenges, ensuring a reliable and durable installation. For example, connectors exposed to direct sunlight may require UV-resistant materials to prevent degradation over time. Similarly, areas prone to extreme temperature changes may benefit from connectors designed to maintain performance across a wider temperature range. By taking these environmental factors into account, contractors can enhance the longevity and reliability of their installations.

Even with the right connectors, improper installation techniques can lead to failures. Common mistakes include inadequate wire stripping, insufficient crimping, and neglecting to apply heat or gel properly. Each of these factors can compromise the waterproof seal and lead to moisture ingress.

To mitigate these risks, contractors should invest time in training and practice. Familiarity with the tools and techniques required for proper installation will enhance overall project quality and reduce the likelihood of callbacks due to connector failures. Moreover, using the right tools for the job is equally important; for instance, a high-quality crimping tool can make a significant difference in achieving a secure connection. Additionally, contractors should consider implementing a quality control checklist during installation to ensure that each step is executed correctly. This proactive approach not only minimizes errors but also fosters a culture of excellence within the team, ultimately leading to better project outcomes.

Implementing best practices when working with waterproof splice connectors can significantly enhance the reliability and safety of electrical installations. These practices encompass everything from selection to installation and maintenance.

Before starting any project, contractors should take the time to research the various waterproof splice connectors available on the market. This research should include understanding the specifications, materials, and intended applications of each connector type. By doing so, contractors can make informed decisions that align with the specific needs of their projects.

Additionally, consulting with manufacturers or suppliers can provide valuable insights into the latest innovations and best practices in connector technology. Staying updated on industry trends can help contractors choose the most effective solutions for their projects. For instance, some connectors may feature advanced sealing technologies that enhance their waterproof capabilities, while others might be designed for specific environmental conditions, such as extreme temperatures or exposure to chemicals. Understanding these nuances can lead to better performance and longevity of the electrical connections.

Every waterproof splice connector comes with manufacturer guidelines that outline the proper installation procedures and best practices. Adhering to these guidelines is crucial for ensuring the connectors perform as intended. This includes recommendations for wire preparation, crimping techniques, and the application of heat or gel.

Contractors should also be aware of any specific safety precautions outlined by the manufacturer. Following these guidelines not only enhances the quality of the installation but also helps ensure compliance with industry standards and regulations. Moreover, manufacturers often provide detailed troubleshooting tips and common pitfalls to avoid, which can be invaluable during the installation process. Familiarizing oneself with these resources can save time and reduce the risk of costly mistakes.

Once waterproof splice connectors are installed, regular maintenance and inspections are essential to ensure continued performance. Over time, environmental factors can take a toll on connectors, leading to wear and tear. Scheduling routine inspections can help identify potential issues before they escalate into significant problems.

During inspections, contractors should check for signs of corrosion, moisture ingress, or physical damage. If any issues are detected, prompt action should be taken to replace or repair the affected connectors. This proactive approach can extend the life of the installation and enhance overall safety. Additionally, keeping a detailed log of inspections and maintenance activities can help track the performance of the connectors over time, providing insights into their durability and the effectiveness of the materials used. This documentation can also be beneficial for future projects, allowing contractors to make data-driven decisions based on past experiences.

Waterproof splice connectors are vital components for any lighting contractor working on outdoor projects. Understanding their types, proper installation techniques, and common mistakes can significantly impact the quality and safety of electrical installations. By avoiding common pitfalls, contractors can ensure that their work stands the test of time, providing reliable service even in challenging conditions.

Implementing best practices, conducting thorough research, and adhering to manufacturer guidelines will not only enhance the quality of installations but also contribute to overall customer satisfaction. As the industry evolves, staying informed about advancements in connector technology and installation techniques will be crucial for lighting contractors aiming to deliver exceptional results.

In conclusion, the importance of waterproof splice connectors cannot be understated. By recognizing and addressing common mistakes, lighting contractors can elevate their work, ensuring safety, reliability, and longevity in their electrical installations.

Ready to avoid common installation mistakes and ensure the longevity of your outdoor lighting projects? Choose LumenWholesale for your waterproof splice connectors and experience the difference quality makes. Our spec-grade lighting products are designed to meet the highest industry standards, providing you with the reliability and performance you need. With unbeatable wholesale prices and the convenience of free shipping on bulk orders, you can trust that you’re getting the best value without any hidden fees. Elevate your lighting installations today by visiting LumenWholesale for Wholesale Lighting at the Best Value.

Illuminate your projects with precision using our comprehensive guide on stair lighting.

Discover why brass recessed lighting is becoming a top choice for lighting contractors.

Discover the essential guidelines for lighting contractors with our comprehensive guide on industrial wall sconces.

Discover how lighting contractors are transforming spaces with innovative utility lighting solutions.