Light Emitting Diodes (LEDs) have revolutionized the lighting industry, offering unparalleled efficiency, longevity, and versatility compared to traditional lighting sources. For lighting contractors, understanding the different kinds of LED technologies and their applications is essential to delivering optimal solutions to clients. This comprehensive checklist covers the key types of LEDs, their characteristics, and practical considerations to help contractors make informed decisions on any project.

With the increasing demand for energy-efficient and sustainable lighting, LEDs dominate both commercial and residential markets. However, the variety of LED types and configurations can be overwhelming. This guide breaks down the essential categories and technical aspects to streamline your selection process and enhance your professional expertise.

Standard indicator LEDs are the small, low-power diodes commonly used for status indicators on devices, control panels, and signage. They typically emit light in a single color, such as red, green, or blue, and operate on very low voltage and current.

For lighting contractors, these LEDs are less about illumination and more about signaling. They are useful in control systems, emergency lighting panels, and equipment status indicators. Their compact size and low power consumption make them ideal for integration into electronic assemblies.

High-power LEDs are designed to produce significantly more light output than standard indicators, often used in general illumination applications. These LEDs can deliver hundreds to thousands of lumens per diode and are commonly found in streetlights, floodlights, and commercial fixtures.

They require careful thermal management, typically through heat sinks or active cooling, to maintain performance and lifespan. Lighting contractors must consider heat dissipation in fixture design to prevent premature failure. High-power LEDs are available in various color temperatures, enabling tailored lighting atmospheres from warm white to daylight.

SMD LEDs are compact, flat LEDs mounted directly onto printed circuit boards (PCBs). They are widely used in LED strip lights, panel lights, and downlights due to their small size and high efficiency.

The versatility of SMD LEDs allows contractors to specify flexible or rigid lighting solutions with customizable lengths and densities. Different SMD types, such as 3528, 5050, and 2835, denote the LED package size and power, influencing brightness and power consumption. Understanding these distinctions helps in selecting the right LED strip for a given project.

COB LEDs consist of multiple LED chips mounted closely together on a single substrate, creating a uniform and intense light source. They are favored for applications requiring high lumen density and smooth light distribution, such as downlights, track lighting, and architectural lighting.

COB technology reduces the number of individual components, simplifying fixture design and improving thermal performance. Contractors appreciate COB LEDs for their high efficacy and clean light output, which enhances visual comfort and reduces glare.

OLEDs emit light through organic compounds and offer unique advantages such as ultra-thin, flexible panels and diffuse, soft lighting. While OLEDs are less common in traditional contractor applications due to cost and lower brightness, they are gaining traction in specialty lighting, decorative fixtures, and automotive interiors.

Lighting contractors should monitor OLED advancements as they may become more viable for ambient and accent lighting, especially in design-focused projects where aesthetics and form factor are paramount.

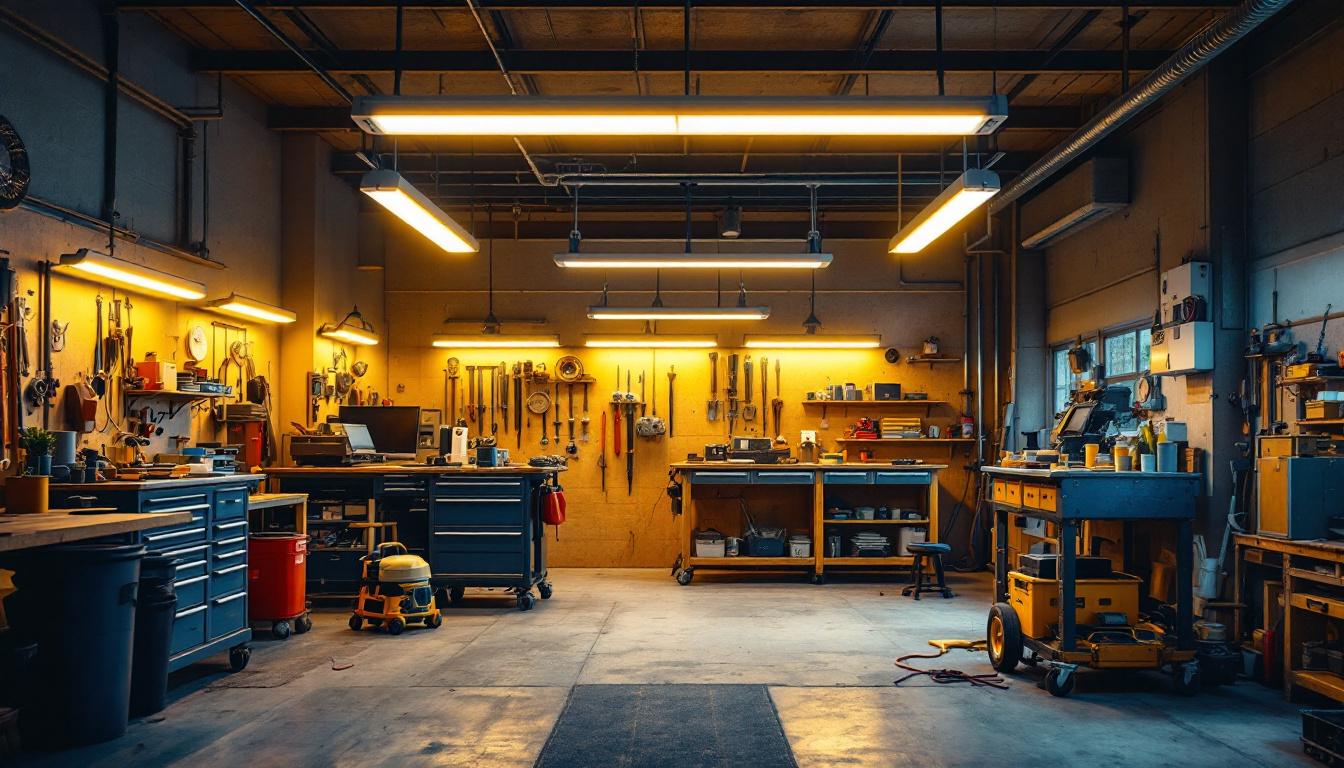

White LEDs are the most prevalent for general lighting and come in various color temperatures measured in Kelvins (K). Warm white (2700K–3000K) produces a cozy, yellowish light ideal for residential and hospitality settings. Neutral white (3500K–4100K) balances warmth and brightness, suitable for offices and retail spaces. Cool white (5000K–6500K) offers crisp, daylight-like illumination preferred in industrial and task-oriented environments.

Lighting contractors must align color temperature choices with client needs and the intended atmosphere. Additionally, LEDs with high Color Rendering Index (CRI) values (above 80, ideally 90+) ensure colors appear natural and vibrant, which is critical in retail, art galleries, and medical facilities.

RGB LEDs combine red, green, and blue diodes to create a broad spectrum of colors through color mixing. These are popular for dynamic lighting effects in entertainment venues, architectural facades, and signage. Tunable white LEDs allow adjustment of color temperature on the fly, enabling users to shift from warm to cool light depending on time of day or activity.

For contractors, integrating RGB or tunable white systems often involves compatible controllers and dimmers. Understanding the wiring, programming, and compatibility requirements is essential to deliver seamless, customizable lighting solutions.

Ultraviolet (UV) and infrared (IR) LEDs serve specialized functions beyond visible illumination. UV LEDs are used in sterilization, counterfeit detection, and curing applications, while IR LEDs are common in security cameras and remote controls.

While not typically part of standard lighting projects, contractors working in niche markets such as healthcare, manufacturing, or security should be familiar with these LEDs to meet unique client demands.

LEDs operate on low voltage DC power, but the specific voltage and current requirements vary widely depending on the LED type and application. Lighting contractors must select appropriate drivers and power supplies that provide stable current to prevent flickering and ensure longevity.

Understanding the difference between constant current and constant voltage drivers is crucial. Constant current drivers maintain a fixed current suitable for high-power LEDs, while constant voltage drivers are used for LED strips and modules with integrated resistors.

Heat is the primary enemy of LED performance and lifespan. Effective thermal management through heat sinks, thermal pads, or active cooling systems is mandatory for high-power and COB LEDs. Contractors should evaluate fixture design and installation environment to mitigate heat buildup.

Failing to address thermal issues can lead to reduced light output, color shifts, and early failure, which negatively impacts client satisfaction and warranty claims.

Dimming LEDs requires compatible drivers and control systems. Not all LEDs dim smoothly; some may flicker or produce noise if paired with incompatible dimmers. Lighting contractors should verify manufacturer specifications and test dimming performance before installation.

Advanced dimming technologies such as 0-10V, DALI, and DMX offer precise control and integration with building automation systems, expanding the possibilities for energy savings and ambiance customization.

The beam angle determines how light is distributed from the LED source. Narrow beam angles (15°–30°) are ideal for spotlighting and accent lighting, while wide beam angles (60°–120°) suit general illumination and area lighting.

Contractors must consider fixture optics, reflectors, and lenses to achieve the desired lighting effect. Proper beam angle selection enhances visual comfort and reduces light pollution or unwanted glare.

Before installation, conduct a thorough site assessment to understand the lighting requirements, existing infrastructure, and environmental conditions. This includes measuring ambient light levels, evaluating mounting surfaces, and identifying power sources.

Planning helps avoid costly modifications and ensures that the selected LED types and fixtures meet performance expectations and regulatory standards.

Adhering to electrical codes and safety standards is non-negotiable. Use appropriate gauge wiring, connectors, and protective devices to handle LED loads safely. Proper grounding and surge protection safeguard against electrical faults and extend system life.

Contractors should stay updated on local regulations and certifications, such as UL, CE, or RoHS compliance, to guarantee product quality and legal compliance.

Although LEDs require less maintenance than traditional lighting, periodic inspections ensure continued performance. Check for signs of overheating, discoloration, or driver malfunctions. Cleaning lenses and heat sinks can prevent dust accumulation that impairs light output and cooling.

Having a troubleshooting checklist for common issues like flickering, dimming failures, or color inconsistencies enables contractors to provide prompt service and maintain client trust.

Integration of LEDs with IoT (Internet of Things) technologies is transforming lighting into intelligent systems capable of adaptive control, energy monitoring, and remote management. Smart LEDs can adjust brightness, color, and scheduling based on occupancy, daylight availability, or user preferences.

Lighting contractors should familiarize themselves with smart platforms and protocols such as Zigbee, Bluetooth Mesh, and Wi-Fi to offer cutting-edge solutions that enhance building efficiency and user experience.

Continuous improvements in semiconductor materials and chip design are pushing LED efficacy beyond 200 lumens per watt in some cases. This progress enables smaller fixtures with higher output and lower energy consumption.

Contractors benefit from staying informed about these advancements to recommend the most cost-effective and sustainable lighting options, helping clients reduce operational costs and environmental impact.

Human-centric lighting (HCL) focuses on the biological effects of light on circadian rhythms, mood, and productivity. LEDs with tunable spectra can simulate natural daylight patterns, supporting occupant well-being in offices, healthcare, and educational environments.

Incorporating HCL principles into lighting designs positions contractors as leaders in health-conscious, innovative lighting solutions that meet evolving client expectations.

For lighting contractors, mastering the diverse landscape of LED technologies is fundamental to delivering high-quality, efficient, and tailored lighting solutions. From understanding the distinctions between SMD and COB LEDs to navigating color temperatures, dimming compatibility, and smart controls, each factor plays a critical role in project success.

By leveraging this ultimate checklist, contractors can confidently specify the right LED types, ensure proper installation, and anticipate future trends, ultimately enhancing client satisfaction and professional reputation in a competitive market.

Ready to elevate your lighting game? Look no further than LumenWholesale for all your LED needs. As a lighting contractor, you understand the importance of quality and cost-efficiency. That’s why we offer an extensive range of spec-grade lighting products at unbeatable wholesale prices, ensuring you don’t just meet but exceed your clients’ expectations. Say goodbye to middlemen and inflated costs, and hello to premium lighting with the convenience of free shipping. Don’t compromise on quality or value; choose LumenWholesale for Wholesale Lighting at the Best Value and make every project shine.

Discover why plug outlet stock is essential for every lighting contractor.

Discover the insider secrets of lighting contractors with our comprehensive guide to track bar lighting.

Discover how low voltage under cabinet lighting is revolutionizing the work of lighting contractors.

Discover the essential guide to choosing and installing LED 8-foot shop lights with our comprehensive contractor checklist.