Waterproof Trailer Wire Connectors: Why it is Critical in Lighting Installations

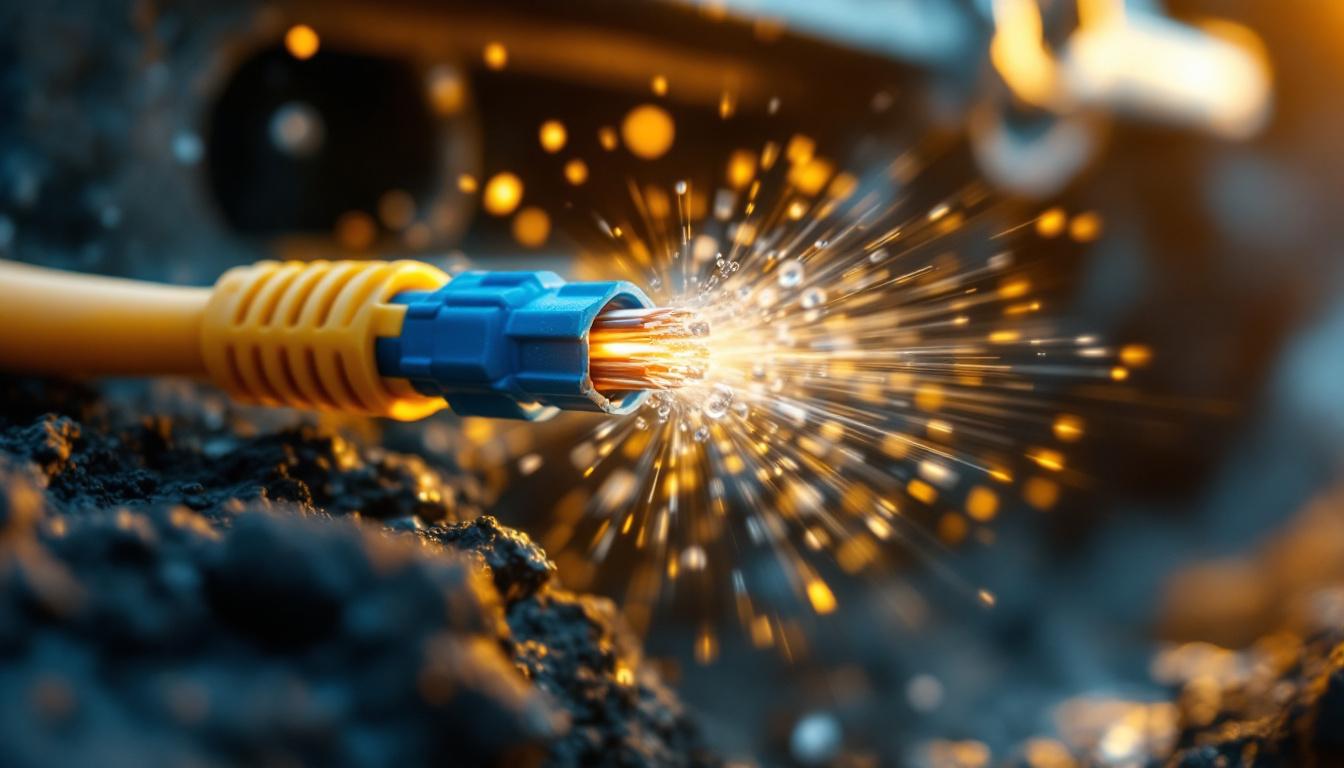

In the world of lighting installations, especially for outdoor and trailer applications, ensuring the integrity and reliability of electrical connections is paramount. One of the most critical components in this regard is the use of waterproof trailer wire connectors. These connectors not only enhance the longevity of lighting systems but also ensure safety and efficiency in operation.

Waterproof connectors are designed to withstand harsh environmental conditions. For lighting contractors, understanding the significance of these connectors can make a substantial difference in the performance and durability of their installations.

Outdoor lighting installations are constantly exposed to moisture, dirt, and varying temperatures. These environmental factors can lead to corrosion and electrical failures if not properly managed. Waterproof trailer wire connectors offer a sealed connection that prevents water ingress, ensuring that the electrical components remain dry and functional.

Moreover, the materials used in waterproof connectors are often resistant to UV rays and other environmental stressors. This durability is essential for maintaining the integrity of the lighting systems over time, minimizing the need for frequent repairs or replacements. In addition to UV resistance, many waterproof connectors are designed with rugged housings that can withstand impacts and vibrations, making them ideal for use in high-traffic areas or locations prone to extreme weather conditions. This added layer of protection not only extends the lifespan of the connectors but also enhances the overall reliability of the lighting systems they support.

Electrical connections that are not adequately protected can pose significant safety risks. Water intrusion can lead to short circuits, which may cause fires or equipment damage. By using waterproof trailer wire connectors, contractors can significantly reduce these risks, ensuring that installations are not only efficient but also safe for end-users.

Additionally, many waterproof connectors come with features such as strain relief and locking mechanisms, which further enhance safety by preventing accidental disconnections and protecting against mechanical stress. These features are particularly important in installations where movement or vibration is common, such as in outdoor events or temporary setups. Furthermore, the ease of installation and maintenance associated with waterproof connectors allows contractors to work efficiently, reducing downtime and ensuring that projects are completed on schedule. This combination of safety, durability, and convenience makes waterproof connectors an invaluable asset in the toolkit of any lighting contractor.

Understanding the different types of waterproof connectors available is crucial for making informed decisions in lighting installations. Each type serves specific applications and offers varying levels of protection.

Sealed connectors are designed to provide a complete barrier against moisture and contaminants. They typically feature an O-ring or silicone seal that ensures a tight fit. These connectors are ideal for applications where exposure to water is frequent, such as in marine environments or during heavy rain.

Contractors often prefer sealed connectors for their reliability and ease of installation. They can be used in various lighting setups, from decorative outdoor fixtures to functional task lighting. Additionally, sealed connectors are often tested for durability, ensuring they can withstand not only water exposure but also extreme temperatures and UV radiation, making them a long-lasting choice for outdoor applications.

Heat shrink connectors offer an additional layer of protection by using heat-activated adhesive that creates a waterproof seal when heated. This type of connector is particularly useful in environments where vibration or movement may occur, as the adhesive helps to secure the connection against mechanical stress.

These connectors are versatile and can be used in both permanent installations and temporary setups. Their ability to conform to various wire sizes makes them a popular choice among lighting contractors. Moreover, heat shrink connectors are often favored for their aesthetic appeal; once installed, they provide a clean and professional look, which is especially important in visible installations like landscape lighting or decorative fixtures.

IP (Ingress Protection) ratings provide a standardized way to measure the effectiveness of connectors against dust and water ingress. Connectors with higher IP ratings, such as IP67 or IP68, offer superior protection and are suitable for the most demanding environments.

When selecting connectors for lighting installations, contractors should consider the specific IP rating required for the application. This ensures that the connectors will perform reliably under the expected conditions. Additionally, understanding the implications of these ratings can help contractors educate clients about the importance of choosing the right connectors, especially in areas prone to harsh weather or dust exposure. For instance, an IP68-rated connector can be submerged in water for extended periods, making it ideal for underwater lighting applications in pools or fountains.

Proper installation of waterproof trailer wire connectors is essential for maximizing their effectiveness. Adhering to best practices can help contractors avoid common pitfalls and ensure long-lasting performance.

Before installation, it is crucial to select the appropriate connector based on the specific requirements of the lighting system. Factors such as wire gauge, environmental conditions, and application type should all influence the choice of connector.

Consulting manufacturer specifications and guidelines can provide valuable insights into which connectors are best suited for particular installations. This proactive approach can prevent complications down the line. Additionally, understanding the differences between various connector types—such as butt connectors, ring terminals, and spade connectors—can further refine the selection process, ensuring that the chosen connector not only fits the wire gauge but also meets the demands of the installation environment.

For connectors designed to be waterproof, ensuring a proper seal is vital. During installation, contractors should carefully follow the manufacturer’s instructions regarding sealing techniques, whether that involves crimping, soldering, or using heat shrink methods.

Additionally, it is important to inspect the connectors after installation to confirm that they are securely fastened and free from any gaps that could allow moisture to enter. Regular maintenance checks can also help identify potential issues before they escalate. Utilizing silicone sealants or dielectric grease can provide an extra layer of protection against moisture intrusion, especially in high-humidity environments or areas prone to water exposure. This added precaution can significantly extend the lifespan of the connectors and the overall wiring system.

Once the connectors are installed, conducting thorough testing is essential. This may include checking for continuity, verifying voltage levels, and ensuring that the connections are functioning as intended. Testing not only confirms the integrity of the installation but also provides peace of mind for both contractors and clients.

Documenting test results can serve as a valuable reference for future maintenance and troubleshooting, creating a comprehensive record of the installation’s performance. Additionally, utilizing advanced testing equipment, such as multimeters and circuit testers, can help identify any intermittent issues that may not be immediately apparent. By implementing a rigorous testing protocol, contractors can ensure that the entire system operates efficiently, reducing the likelihood of unexpected failures and enhancing the reliability of the lighting system over time.

Despite the advantages of waterproof trailer wire connectors, lighting contractors may encounter challenges during installation and maintenance. Understanding these challenges and their solutions can enhance overall project success.

Corrosion can occur even with waterproof connectors if they are not installed correctly or if the environment is particularly harsh. To mitigate this risk, contractors should use connectors made from corrosion-resistant materials, such as stainless steel or specific alloys.

Additionally, applying protective coatings or greases can further enhance resistance to corrosion. Regular inspections can help identify early signs of corrosion, allowing for timely intervention before significant damage occurs. It is also beneficial for contractors to educate their teams on best practices for installation, such as ensuring that connectors are not exposed to standing water or excessive moisture during the installation process. This proactive training can significantly reduce the likelihood of corrosion-related issues down the line.

Another common challenge is ensuring compatibility between different types of connectors and wiring systems. Mismatched connectors can lead to poor performance or even failure. To avoid this issue, contractors should always verify that the connectors are compatible with the specific wiring and equipment being used.

Utilizing standardized connectors can simplify this process, as they are designed to work seamlessly with a variety of systems. Keeping abreast of industry standards can also help contractors make informed decisions regarding connector selection. Additionally, maintaining a well-organized inventory of connectors and their specifications can streamline the installation process, reducing the chances of errors and improving overall efficiency on the job site.

Different environments present unique challenges for electrical installations. For example, coastal areas may have higher levels of salt and humidity, while industrial sites may expose connectors to chemicals and pollutants. Understanding these environmental factors is crucial for selecting the right connectors.

Contractors should consider the specific conditions of each installation site and choose connectors that are rated for those environments. This proactive approach can significantly enhance the longevity and reliability of the lighting systems. Furthermore, implementing a routine maintenance schedule that includes cleaning and inspection of connectors can help ensure that they remain in optimal condition. By being vigilant about environmental factors and their impact on connector performance, contractors can better safeguard their installations against potential failures and costly repairs.

Waterproof trailer wire connectors play a critical role in the success of lighting installations, particularly in outdoor and challenging environments. By providing protection against moisture, enhancing safety, and ensuring reliable connections, these connectors are indispensable for lighting contractors.

Understanding the various types of waterproof connectors, adhering to best installation practices, and proactively addressing common challenges can lead to successful outcomes in lighting projects. As the demand for durable and efficient lighting solutions continues to grow, the importance of waterproof connectors will remain a key consideration for contractors in the field.

Ready to elevate your lighting installations with the highest quality waterproof trailer wire connectors? Look no further than LumenWholesale. Our spec-grade lighting products are designed to meet the rigorous demands of any project while offering the best value through wholesale pricing. Say goodbye to local distributor markups and hello to our extensive selection of reliable, high-performance lighting essentials. With LumenWholesale, bulk buying is a breeze, and with free shipping, you can rest assured that you’re getting premium products at the most competitive prices. Don’t compromise on quality or cost—Wholesale Lighting at the Best Value is just a click away.

Discover essential insights for lighting contractors in our comprehensive guide on loading dock lights.

Discover how lighting contractors can benefit from the 14,000/4 approach, unlocking increased efficiency, cost savings, and competitive advantage—learn more now!.

Discover innovative hacks for smart lighting contractors to enhance exterior lamp post lights.

Discover the best practices lighting contractors use to enhance curb appeal and security with outdoor spotlights.