In the competitive world of lighting contracts, standing out from the crowd can be a daunting task. As a lighting contractor, the quality of materials used in your projects can significantly influence your reputation and success. One of the most crucial components that can enhance your offerings is waterproof electrical wire. This article explores how integrating waterproof electrical wire into your projects can help you secure more contracts and provide better service to your clients.

Waterproof electrical wire is specifically designed to withstand exposure to moisture, making it an essential choice for outdoor and damp environments. Unlike standard electrical wiring, which can corrode or short-circuit when exposed to water, waterproof options are built with materials that resist degradation and maintain functionality over time. This resilience is particularly important in regions with high humidity or frequent rainfall, where traditional wiring would quickly fail, leading to costly repairs and safety hazards.

There are several types of waterproof electrical wires available, each suited for different applications. The most common types include:

Choosing the right type of waterproof wire is crucial for ensuring the longevity and safety of your lighting projects. It is also important to consider local building codes and regulations, which may dictate specific types of wiring for certain installations, especially in areas prone to flooding or high moisture levels.

The advantages of using waterproof electrical wire extend beyond mere functionality. Here are some key benefits:

Additionally, waterproof electrical wires often come with UV-resistant coatings, which protect them from the damaging effects of sunlight. This feature is particularly important for installations that are exposed to direct sunlight for extended periods. Furthermore, many waterproof wires are also resistant to chemicals and abrasion, making them suitable for use in industrial environments where exposure to harsh substances is a concern. By investing in high-quality waterproof wiring, you ensure that your electrical systems remain reliable and efficient, regardless of the conditions they face.

Integrating waterproof electrical wire into your projects can significantly enhance your competitiveness in the lighting market. Here’s how it can help you win more contracts:

Clients today are more informed than ever about the materials used in their projects. By offering waterproof electrical wire, you demonstrate a commitment to quality and safety, which can set you apart from competitors who may not prioritize these aspects. Clients are likely to appreciate the added durability and safety features, making them more inclined to choose your services over others. Furthermore, as weather patterns become increasingly unpredictable, the demand for robust solutions that can withstand the elements is on the rise. By proactively addressing these concerns with waterproof wiring, you not only meet but exceed client expectations, fostering trust and long-term relationships.

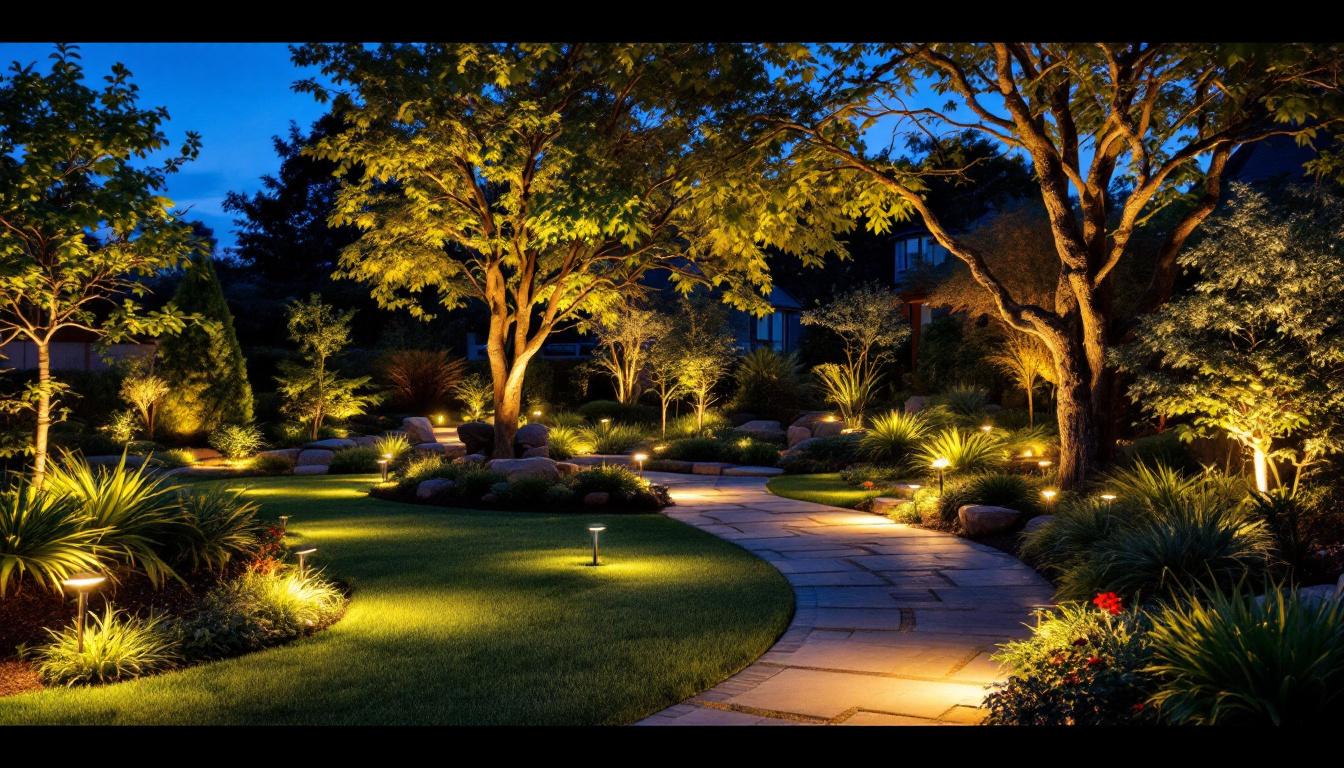

With waterproof electrical wire, contractors can expand their service offerings to include outdoor lighting, landscape lighting, and installations in high-moisture areas. This versatility not only opens up new revenue streams but also positions you as a comprehensive solution provider. Clients looking for a contractor who can handle diverse lighting needs will find your services more appealing. Additionally, the ability to tackle projects in various environments—such as pools, spas, and coastal areas—allows you to cater to a broader clientele. By showcasing your expertise in these specialized installations, you can attract high-end projects that demand meticulous attention to detail and superior materials.

Quality workmanship and materials lead to satisfied clients, which in turn fosters positive word-of-mouth referrals. By consistently using waterproof electrical wire in your projects, you can build a reputation for reliability and excellence. Over time, this reputation will translate into more contracts as clients and industry peers recognize your commitment to quality. Moreover, leveraging testimonials and case studies that highlight successful installations can further bolster your credibility. Sharing these stories on your website and social media platforms not only showcases your expertise but also engages potential clients who are looking for proven solutions. As your portfolio grows, so too will your visibility in the market, making you a go-to contractor for waterproof electrical installations.

While the benefits of waterproof electrical wire are clear, it is essential to understand the technical aspects to ensure proper installation and compliance with local codes.

Proper installation is critical to maximizing the benefits of waterproof electrical wire. Here are some guidelines to follow:

Additionally, it is advisable to consider the environmental conditions where the wire will be installed. For instance, in areas with high humidity or exposure to saltwater, selecting wires with enhanced corrosion resistance can significantly prolong their lifespan. Furthermore, when running wires through conduits, ensure that they are adequately sized to prevent overheating, which can compromise the waterproofing features of the wire. Regular inspections during and after installation can also help identify any potential issues early on, allowing for timely interventions.

Understanding and complying with local electrical codes is crucial when working with waterproof electrical wire. These codes often dictate the types of materials and installation methods that are acceptable. Ensuring compliance not only enhances safety but also protects your business from potential liabilities.

Moreover, it is important to stay updated with any changes in electrical codes, as these regulations can evolve based on new safety standards and technological advancements. Engaging with local electrical inspectors during the planning phase can provide valuable insights and help clarify any ambiguities regarding compliance. Additionally, maintaining detailed records of the materials used and the installation process can serve as a safeguard in case of inspections or audits, ensuring that all practices align with the latest safety protocols and best practices in the industry.

Investing in waterproof electrical wire may initially appear to be a higher upfront cost compared to standard wiring options. However, the long-term benefits often outweigh these initial expenses.

While waterproof electrical wire may come with a higher price tag, its durability and resistance to moisture-related issues can lead to significant long-term savings. Fewer repairs and replacements mean lower maintenance costs, allowing contractors to allocate resources more efficiently.

When considering the pricing of projects that utilize waterproof electrical wire, it’s essential to communicate the value to clients. Highlighting the benefits of using superior materials can justify the investment. Offering tiered pricing options based on the type of wiring used can also attract a broader range of clients.

Real-world examples can illustrate the advantages of using waterproof electrical wire in various lighting projects. Here are a couple of case studies that demonstrate its effectiveness:

A lighting contractor was tasked with designing an outdoor lighting system for a residential property. By using waterproof electrical wire, the contractor ensured that the installation could withstand the elements, including rain and snow. The homeowner was thrilled with the results, leading to referrals for additional projects in the neighborhood.

In another instance, a contractor was hired to install landscape lighting for a commercial property. The use of waterproof electrical wire allowed for a seamless installation around water features and in areas prone to flooding. The project was completed on time and within budget, earning the contractor a long-term maintenance contract with the client.

Incorporating waterproof electrical wire into your projects is not just a technical choice; it is a strategic business decision. By enhancing the quality and safety of your installations, you can meet and exceed client expectations, expand your service offerings, and build a strong reputation in the industry.

As the lighting market continues to evolve, staying ahead of the competition requires innovation and a commitment to quality. Waterproof electrical wire is a key component that can help lighting contractors secure more contracts and foster lasting client relationships. Embrace this opportunity to elevate your business and set yourself apart in a crowded marketplace.

Ready to take your lighting projects to the next level with waterproof electrical wire and secure more contracts? Look no further than LumenWholesale. Our commitment to providing contractors with top-quality, spec-grade lighting products at unbeatable wholesale prices means you can trust us to supply the reliable, high-performance lighting essentials your business needs. With our hassle-free bulk buying options and free shipping, you’ll enjoy the best value without any hidden fees. Elevate your lighting business today and experience the best in wholesale lighting at LumenWholesale.

Discover why purchasing dusk to dawn lights in bulk from local distributors might not be the best choice.

Discover the key insights into client expectations for bathroom lighting projects.

Discover expert tips on optimizing your living room ceiling lighting for maximum efficiency.

Discover common overlooked aspects of landscaping lights LED systems, learn expert tips, and enhance your outdoor lighting for beauty, safety, and energy savings..