In the realm of electrical installations, particularly for lighting systems, the type of plugs used for dryers can often be overlooked. However, understanding these plugs is crucial for ensuring safety, efficiency, and compliance with electrical codes. This article delves into the various types of dryer plugs and their significance in lighting installations.

Dryers typically require specific types of plugs that connect to dedicated circuits. These plugs are designed to handle high voltage and current, which is essential for the operation of heavy-duty appliances. When lighting contractors are aware of the different types of plugs available, they can make informed decisions that enhance the overall safety and functionality of their projects.

Choosing the right plug for a dryer is not just about compatibility; it also involves understanding the electrical load and ensuring that the installation adheres to local codes. An improper plug can lead to overheating, electrical fires, and equipment damage. Therefore, lighting contractors must prioritize the selection of appropriate plugs when integrating dryer circuits into their designs.

Moreover, the choice of plugs can affect the overall efficiency of the electrical system. A poorly selected plug may cause voltage drops, leading to inadequate power supply for lighting fixtures. Thus, understanding the different types of plugs available is essential for optimizing performance in lighting installations.

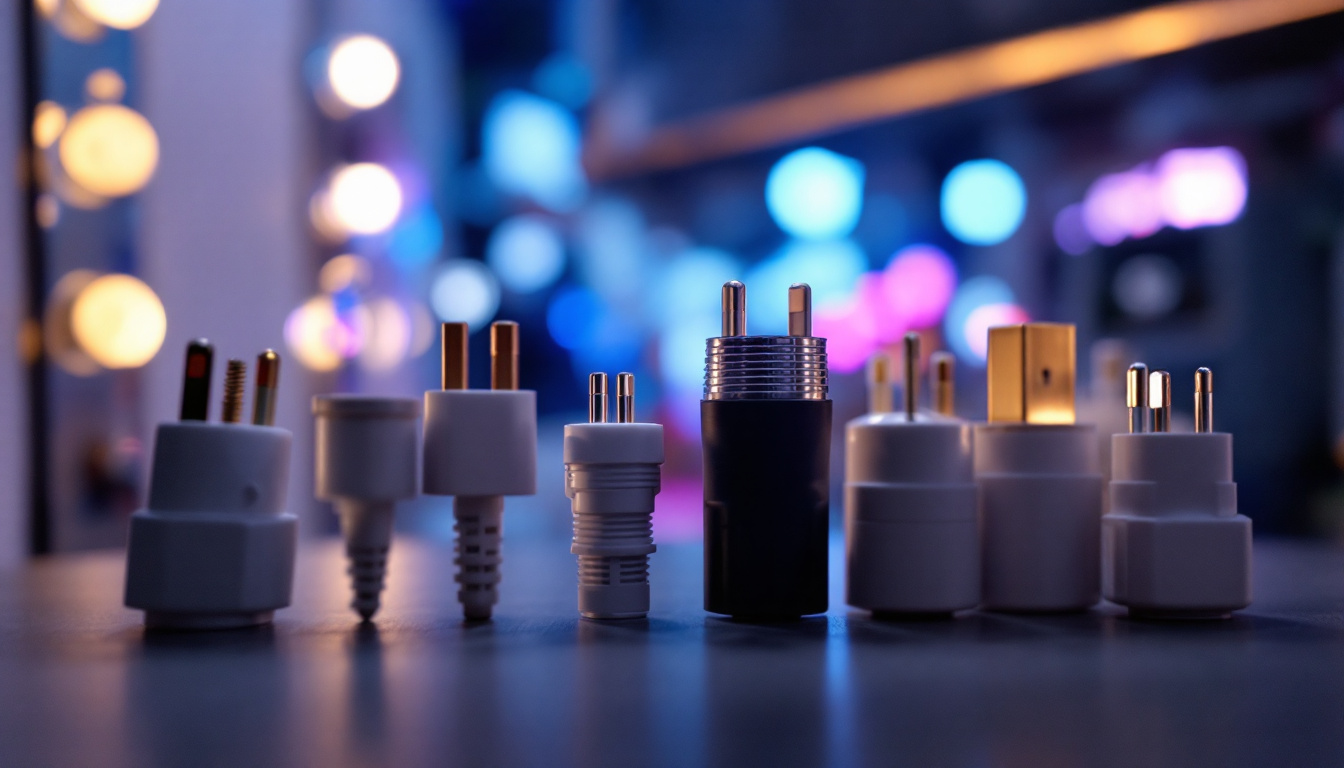

In addition to safety and efficiency, the physical characteristics of dryer plugs also play a significant role in their application. For instance, the NEMA (National Electrical Manufacturers Association) configurations define the specific shapes and pin arrangements that ensure proper connections. Common types include the NEMA 10-30 and NEMA 14-30, each designed for different amperage ratings and voltages. By familiarizing themselves with these configurations, lighting contractors can ensure that they select plugs that not only meet the electrical demands but also fit seamlessly into the overall design of the installation.

Furthermore, advancements in technology have introduced smart plugs that offer enhanced functionality, such as energy monitoring and remote control capabilities. These modern solutions can be particularly beneficial in commercial settings, where energy efficiency is paramount. By integrating smart dryer plugs, contractors can provide clients with the ability to track energy usage and optimize their electrical systems, ultimately leading to cost savings and a reduced carbon footprint. As the landscape of electrical installations continues to evolve, staying informed about these innovations will empower contractors to deliver cutting-edge solutions that meet the needs of today’s energy-conscious consumers.

There are several types of dryer plugs, each designed for specific voltage and amperage requirements. The most common types include NEMA 10, NEMA 14, and NEMA 6 plugs. Each of these plugs has unique characteristics that make them suitable for different applications.

NEMA 10 plugs were commonly used in older dryer installations and are designed for 240-volt circuits. These plugs typically have three prongs: two hot wires and one neutral wire. While they were widely used in the past, they do not have a ground wire, which raises safety concerns.

For lighting contractors, understanding the limitations of NEMA 10 plugs is essential. Since they lack a ground, using them in new installations is generally discouraged. However, they may still be encountered in older buildings, necessitating careful consideration when planning upgrades or replacements. It’s important to note that many local electrical codes have evolved to prioritize safety, and this has led to a gradual phase-out of NEMA 10 plugs in favor of more secure alternatives. Contractors should also educate homeowners about the potential risks associated with these outdated plugs, particularly in terms of electrical shock and fire hazards.

NEMA 14 plugs are the modern standard for dryer connections and are designed for 240-volt circuits with a four-prong configuration. This includes two hot wires, one neutral wire, and one ground wire, enhancing safety by providing a proper grounding path.

For lighting installations, NEMA 14 plugs are preferable due to their safety features. The inclusion of a ground wire helps prevent electrical shock and reduces the risk of fire hazards. Lighting contractors should advocate for the use of NEMA 14 plugs in new installations to ensure compliance with current electrical codes. Additionally, the versatility of NEMA 14 plugs allows them to be used not only for dryers but also for other high-powered appliances, making them a practical choice in modern homes. This adaptability means that contractors can standardize their installations, simplifying maintenance and future upgrades.

NEMA 6 plugs are another option, typically used for 240-volt appliances that do not require a neutral wire. These plugs come in various configurations, including 20-amp and 30-amp variants, making them suitable for different applications.

While NEMA 6 plugs are less common for dryers, they may be encountered in specific scenarios, such as in commercial settings or when connecting industrial-grade equipment. Lighting contractors should be aware of these plugs and their applications to ensure proper integration into electrical systems. The robust design of NEMA 6 plugs makes them particularly well-suited for environments where heavy machinery is used, as they can handle higher amperage without overheating. Understanding the nuances of these plugs can help contractors make informed decisions about equipment compatibility and safety measures, especially when working in settings that demand high performance and reliability.

Compliance with electrical codes is paramount in any installation, particularly when it involves high-voltage equipment. The National Electrical Code (NEC) outlines specific requirements for dryer plugs, including their configuration and installation practices. Lighting contractors must familiarize themselves with these codes to avoid potential legal issues and ensure the safety of their installations.

Using the appropriate plugs not only adheres to code but also enhances the safety of the overall electrical system. Proper grounding and circuit design can prevent electrical hazards, protecting both the equipment and the individuals who operate it.

Grounding is a critical aspect of electrical safety. In installations that involve dryer plugs, ensuring that all components are properly grounded is essential. This is particularly true for NEMA 14 plugs, which provide a dedicated ground wire.

Lighting contractors should conduct thorough inspections of existing installations to verify that grounding is in place. In cases where older NEMA 10 plugs are still in use, upgrading to NEMA 14 plugs can significantly enhance safety and compliance with modern standards.

Understanding the electrical load is vital when selecting plugs for dryers. Each type of plug is designed to handle specific amperage, and exceeding these limits can lead to overheating and potential fire hazards. Lighting contractors must perform load calculations to ensure that the selected plugs can safely accommodate the electrical demands of the appliances they are connected to.

For instance, a 30-amp NEMA 14 plug should only be used with appliances that draw up to 30 amps. If the load exceeds this limit, it may be necessary to upgrade the circuit or choose a different plug type to ensure safety and compliance.

Integrating dryer circuits into lighting installations can be a complex task. It requires careful planning and consideration of various factors, including plug types, load calculations, and compliance with electrical codes. Lighting contractors must take a holistic approach to ensure that all components work together seamlessly.

One common scenario involves the installation of laundry rooms that also serve as utility spaces for lighting fixtures. In such cases, it is essential to ensure that the dryer plug is easily accessible while maintaining a safe distance from lighting components.

When designing lighting installations that incorporate dryer circuits, several key considerations should be taken into account. The location of the dryer plug should be strategically placed to avoid interference with lighting fixtures and to ensure that it is easily accessible for maintenance and operation.

Additionally, the overall layout should account for the electrical load of both the dryer and the lighting fixtures. Proper circuit design can help prevent overloads and ensure that both systems function efficiently.

As technology continues to evolve, lighting contractors should consider future-proofing their installations. This involves selecting plugs and circuits that can accommodate potential upgrades or changes in electrical demand. For example, opting for higher amperage plugs may be beneficial if there is a possibility of adding more appliances or lighting fixtures in the future.

Future-proofing not only enhances the longevity of the installation but also provides peace of mind for both contractors and clients. By anticipating future needs, contractors can avoid costly upgrades and ensure that the electrical system remains efficient and compliant.

In conclusion, the selection of dryer plugs is a critical aspect of electrical installations, particularly in lighting systems. Understanding the different types of plugs, their applications, and the associated safety considerations is essential for lighting contractors. By prioritizing proper plug selection and adhering to electrical codes, contractors can enhance the safety and efficiency of their installations.

As the industry continues to evolve, staying informed about the latest standards and technologies will empower lighting contractors to make informed decisions. Ultimately, the right plug can make a significant difference in the performance and safety of electrical systems, ensuring that both contractors and clients can enjoy peace of mind.

Ready to elevate your lighting installations with the right dryer plugs and high-quality lighting products? Look no further than LumenWholesale, where we offer an extensive selection of spec-grade lighting essentials at unbeatable wholesale prices. Say goodbye to inflated markups and hello to top-tier lighting solutions that meet the highest industry standards. With free shipping on bulk orders, you can stock up on reliable, high-performance lighting without the hidden fees. Don’t compromise on quality or value—visit LumenWholesale today and discover the perfect blend of affordability and convenience for all your lighting project needs.

Discover essential insights and expert advice for lighting contractors in our comprehensive guide on Light Bulb Depot.

Discover the top benefits of solar-powered flood lights for lighting contractors, including cost efficiency, sustainability, and ease of installation.

Discover innovative hacks for smart lighting contractors to enhance walkways with solar lights.

Discover essential tips and common pitfalls for lighting contractors working with LED strip light kits.