Lighting projects can be intricate and demanding, especially when it comes to choosing the right fixtures. Among the various options available, T8 fluorescent fixtures stand out due to their efficiency and versatility. However, improper planning and execution can lead to costly mistakes. This article aims to guide lighting contractors through the essential considerations to avoid pitfalls in T8 fluorescent lighting projects.

T8 fluorescent fixtures utilize a specific type of bulb that is 1 inch in diameter, offering a balance of efficiency and brightness. They are widely used in commercial and industrial settings due to their ability to provide consistent illumination over large areas. Understanding the technical specifications and advantages of T8 fixtures is crucial for making informed decisions in lighting projects.

One of the primary advantages of T8 fluorescent fixtures is their energy efficiency. Compared to older T12 fixtures, T8 options consume less power while delivering similar or even superior light output. This translates to lower energy bills and a reduced carbon footprint, making them an environmentally friendly choice.

Additionally, T8 fixtures have a longer lifespan, which means less frequent replacements and lower maintenance costs. The longevity of these fixtures can significantly impact the overall budget of a lighting project, making them a wise investment for contractors looking to maximize value. In fact, many T8 bulbs can last up to 30,000 hours, which is significantly longer than their T12 counterparts. This durability not only reduces the hassle of frequent bulb changes but also minimizes waste, aligning with sustainability goals that many businesses strive to achieve.

T8 fluorescent fixtures are versatile and can be used in various applications, including offices, warehouses, retail spaces, and educational institutions. Their ability to provide uniform lighting makes them ideal for environments where visibility is crucial. Understanding the specific needs of each application can help contractors select the appropriate fixtures and configurations. For instance, in a warehouse setting, T8 fixtures can be strategically placed to enhance safety by illuminating walkways and work areas, thereby reducing the risk of accidents.

Moreover, in office environments, T8 fixtures can be paired with dimming controls to create a more adaptable lighting solution. This flexibility allows for adjustments based on the time of day or specific tasks, promoting productivity and comfort among employees. Additionally, the color temperature of T8 bulbs can vary, allowing businesses to choose warmer tones for a cozy atmosphere or cooler tones for a more energizing effect. This adaptability makes T8 fixtures not just a practical choice, but also a customizable one that can enhance the overall ambiance of a space.

Proper planning is essential to avoid mistakes in any lighting project. For T8 fluorescent fixtures, this involves several key steps that ensure the final outcome meets both aesthetic and functional requirements.

Before selecting fixtures, it is vital to conduct a thorough assessment of the space. Consider the dimensions, layout, and purpose of the area. For instance, a warehouse may require different lighting solutions compared to an office space. Understanding the specific lighting needs will help in determining the number and placement of fixtures.

Additionally, take into account any architectural features that may affect lighting, such as windows or high ceilings. These elements can influence how light is distributed and may necessitate adjustments to the initial plan. For example, natural light from windows can reduce the need for artificial lighting during the day, but it may also create glare or uneven lighting conditions. Therefore, it’s essential to evaluate how the natural light interacts with the artificial light sources to create a balanced and inviting atmosphere.

Light levels, measured in foot-candles, are critical for ensuring that a space is adequately illuminated. Different tasks require varying light levels; for example, a classroom may need around 50 foot-candles, while a warehouse might require only 20. Utilizing lighting calculation software can assist in determining the appropriate number of T8 fixtures needed to achieve the desired light levels.

It is also important to consider the color temperature of the T8 bulbs. Warmer temperatures (around 3000K) create a cozy atmosphere, while cooler temperatures (5000K or higher) are more suitable for work environments. Selecting the right color temperature can enhance productivity and comfort in the space. Moreover, consider the use of dimmable fixtures, which can provide flexibility in adjusting light levels based on the time of day or specific activities taking place. This adaptability not only contributes to energy savings but also allows for a more personalized lighting experience, catering to the varying needs of occupants throughout the day.

Even with careful planning, mistakes can still occur during the execution of a lighting project. Here are some common pitfalls to avoid when working with T8 fluorescent fixtures.

One of the most significant mistakes contractors can make is improper fixture placement. Fixtures should be positioned to minimize shadows and ensure even light distribution. Inadequate spacing can lead to dark spots, which can affect functionality and safety.

To avoid this issue, use a lighting layout plan that considers the beam spread of the T8 fixtures. This plan should take into account the height of the fixtures, the type of lens used, and the overall design of the space. Engaging with a lighting designer can provide valuable insights into optimal fixture placement.

While T8 fluorescent fixtures are generally energy-efficient, it is essential to consider the entire lighting system’s efficiency. This includes the use of appropriate ballasts, which can significantly impact energy consumption. Electronic ballasts offer better performance and energy savings compared to magnetic ballasts.

Moreover, incorporating controls such as dimmers and occupancy sensors can further enhance energy efficiency. These technologies allow for better management of lighting based on occupancy and natural light levels, reducing unnecessary energy use.

The components used in a T8 fluorescent lighting system play a critical role in its overall performance. Selecting high-quality fixtures, ballasts, and bulbs can prevent issues down the line and ensure a successful project.

Not all T8 fixtures are created equal. It is crucial to choose fixtures from reputable manufacturers that adhere to industry standards. High-quality fixtures are designed to provide consistent performance and durability, reducing the likelihood of failures and maintenance issues.

Additionally, consider the fixture’s design and materials. Fixtures made from durable materials can withstand wear and tear, especially in commercial settings where they may be exposed to harsh conditions.

The ballast is a critical component that regulates the current to the T8 bulbs. Selecting the right ballast can enhance the performance and lifespan of the lighting system. Electronic ballasts are recommended for T8 fixtures due to their efficiency and ability to provide flicker-free operation.

When choosing a ballast, ensure it is compatible with the selected T8 bulbs. Mismatched components can lead to performance issues and may void warranties. Always refer to manufacturer guidelines for compatibility information.

Proper installation is vital for the success of any lighting project. Adhering to best practices during the installation of T8 fluorescent fixtures can prevent issues and ensure optimal performance.

Each T8 fixture comes with specific installation instructions provided by the manufacturer. Following these guidelines is crucial for ensuring safety and performance. This includes proper wiring, fixture mounting, and ballast installation.

Contractors should also be aware of local electrical codes and regulations that may affect installation. Compliance with these codes is not only a legal requirement but also essential for the safety of the installation.

After installation, it is essential to conduct thorough testing and commissioning of the lighting system. This process involves verifying that all fixtures are functioning correctly and that light levels meet the specified requirements.

Testing should include checking for flickering, color consistency, and overall light distribution. Any issues identified during this phase should be addressed before the project is considered complete. Proper commissioning ensures that the lighting system operates as intended and meets the client’s expectations.

Once the T8 fluorescent lighting system is installed, ongoing maintenance is necessary to ensure its longevity and performance. Regular maintenance can prevent costly repairs and replacements down the line.

Conducting regular inspections of the lighting system is essential for identifying potential issues early on. This includes checking for burnt-out bulbs, damaged fixtures, and any signs of wear and tear. Addressing these issues promptly can prevent more significant problems in the future.

Additionally, consider creating a maintenance schedule that outlines when inspections and replacements should occur. This proactive approach can help maintain optimal performance and extend the lifespan of the lighting system.

As technology advances, upgrading components of the T8 fluorescent lighting system may become necessary. This could involve replacing older ballasts with more efficient models or switching to newer, more energy-efficient bulbs.

Staying informed about advancements in lighting technology can help contractors make informed decisions about upgrades. Implementing these changes can enhance energy efficiency and improve overall lighting quality.

In conclusion, T8 fluorescent fixtures offer a reliable and efficient lighting solution for various applications. However, avoiding costly mistakes in lighting projects requires careful planning, attention to detail, and adherence to best practices. By understanding the benefits of T8 fixtures, assessing the space, and following proper installation and maintenance procedures, lighting contractors can ensure successful outcomes for their projects.

Ultimately, investing time and resources into the planning and execution of T8 fluorescent lighting projects will not only enhance the quality of the installation but also contribute to long-term client satisfaction and project success.

Ready to elevate your lighting projects with the efficiency and reliability of T8 fluorescent fixtures? At LumenWholesale, we provide lighting contractors like you with the highest quality, spec-grade lighting products at unbeatable wholesale prices. Say goodbye to inflated markups and hello to superior lighting solutions that meet the highest industry standards. With our hassle-free bulk buying and free shipping, you can ensure every project shines brightly without breaking the bank. Don’t compromise on quality or value—discover the best wholesale lighting deals at LumenWholesale today.

Discover how outdoor motion detector sensors can revolutionize your lighting design, enhancing security and energy efficiency while adding a touch of modern sophistication to your outdoor spaces..

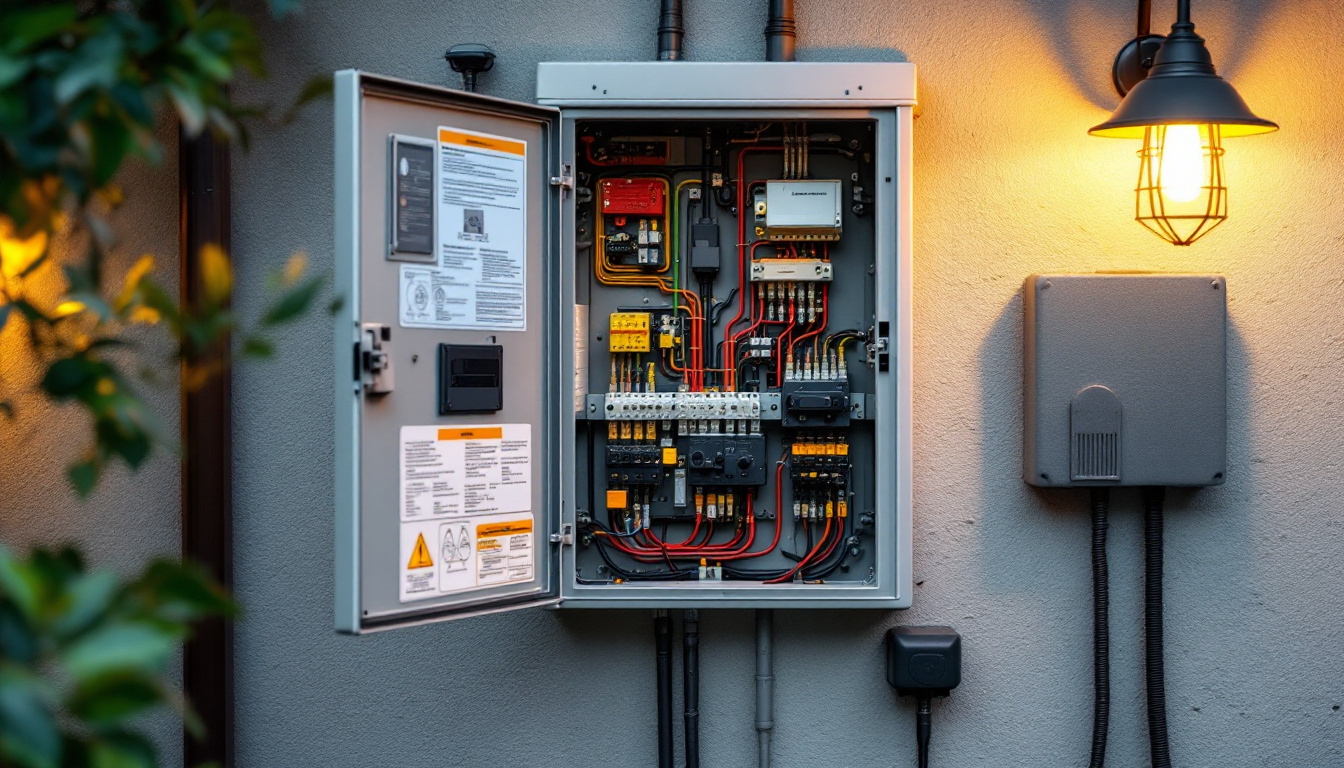

Unlock the secrets of exterior electrical boxes with this essential guide for lighting contractors.

Discover how motion sensing can light enhances safety in lighting installations, reduces energy costs by up to 30%, and offers smart, hands-free control—boost your security today!.

Discover the secrets to mastering motion lighting for outdoor spaces with expert insights from top lighting contractors.