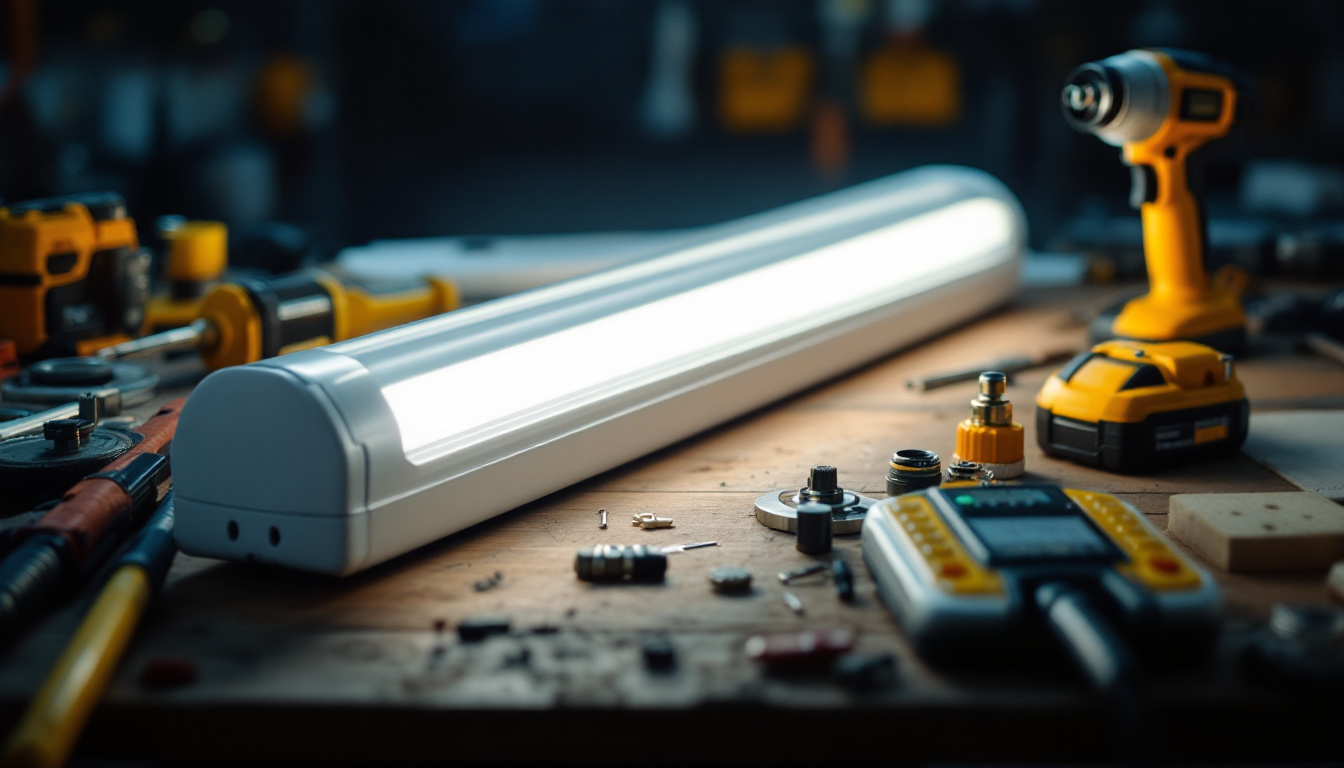

Fluorescent Tube Ballast: essential tools for lighting contractors

In the realm of electrical and lighting work, fluorescent tube ballasts play a crucial role in ensuring the efficient operation of fluorescent lighting systems. For lighting contractors, understanding the function and types of ballasts is essential for providing quality service and maintaining customer satisfaction. This article delves into the various aspects of fluorescent tube ballasts, their importance, and how they can impact the overall lighting experience.

At its core, a fluorescent tube ballast is an electrical device that regulates the current flowing to a fluorescent lamp. It serves two primary functions: providing the necessary starting voltage to ignite the lamp and controlling the current during operation to prevent overheating. Without a proper ballast, fluorescent lamps would flicker, dim, or fail to start altogether.

Fluorescent ballasts can be categorized into two main types: magnetic and electronic. Each type has its own set of characteristics, advantages, and applications.

Magnetic ballasts are the traditional type of ballast, utilizing electromagnetic coils to regulate the current. They are known for their durability and reliability, often lasting for many years. However, they tend to be bulkier and less energy-efficient compared to their electronic counterparts. Magnetic ballasts also produce a noticeable hum and flicker, which can be a drawback in certain settings. In addition, their slower response time can lead to a longer warm-up period for the lamps, which may not be ideal in environments where immediate lighting is necessary, such as in retail spaces or emergency exits.

Electronic ballasts, on the other hand, are more modern and efficient. They use electronic circuits to control the current, resulting in a quieter operation with minimal flicker. These ballasts are typically lighter and more compact, making them easier to install in tight spaces. Additionally, electronic ballasts can improve the overall energy efficiency of fluorescent lighting systems, leading to lower electricity costs for clients. They also offer features like dimming capabilities and compatibility with a wider range of fluorescent lamps, allowing for greater flexibility in lighting design. This adaptability makes electronic ballasts particularly suitable for applications in offices and schools, where lighting needs can vary throughout the day.

Choosing the appropriate ballast for a specific application is critical for ensuring optimal performance and longevity of fluorescent lamps. Factors such as lamp type, wattage, and the intended environment all play a role in this decision-making process.

For instance, using an electronic ballast with a high-efficiency fluorescent lamp can maximize energy savings and enhance light quality. Conversely, pairing a magnetic ballast with a lamp designed for electronic operation may lead to poor performance and reduced lifespan. Furthermore, it is essential to consider the installation environment; for example, ballasts used in damp or outdoor settings must be rated for such conditions to prevent moisture damage. Understanding these nuances not only helps in selecting the right ballast but also contributes to the overall effectiveness and sustainability of the lighting system, ensuring that it meets both functional and aesthetic needs in various environments.

When it comes to installing fluorescent tube ballasts, lighting contractors must adhere to best practices to ensure safety and efficiency. Proper installation not only enhances the performance of the lighting system but also minimizes the risk of future issues.

Before beginning any installation work, it is essential to prioritize safety. This includes turning off power to the circuit, using insulated tools, and wearing appropriate personal protective equipment (PPE). Additionally, contractors should familiarize themselves with local electrical codes and regulations to ensure compliance during the installation process. Regular safety training and drills can also be beneficial, as they keep the team updated on the latest safety protocols and reinforce the importance of vigilance on the job site.

Correct wiring is vital for the successful operation of fluorescent tube ballasts. Contractors should carefully follow the manufacturer’s wiring diagrams and instructions. Ensuring secure connections will help prevent issues such as flickering lights or ballast failure. Furthermore, it is advisable to double-check all connections before powering on the system to catch any potential errors early on.

It is also important to use the correct gauge of wire and connectors to handle the ballast’s current load. Overheating can occur if the wiring is inadequate, leading to potential hazards and costly repairs. Beyond just the technical aspects, contractors should also consider the environmental impact of their installations. Using energy-efficient ballasts can significantly reduce electricity consumption, contributing to lower utility bills and a smaller carbon footprint. Additionally, educating clients about the benefits of energy-efficient lighting options can enhance customer satisfaction and encourage sustainable practices in their facilities.

Regular maintenance and troubleshooting are essential for keeping fluorescent lighting systems in optimal condition. Lighting contractors should be equipped with the knowledge and tools necessary to address common issues that may arise with ballasts. This proactive approach not only enhances the longevity of the lighting systems but also ensures energy efficiency, which can lead to significant cost savings for clients over time.

Identifying the signs of a failing ballast can save time and resources in the long run. Common indicators include flickering lights, dimming, or complete lamp failure. If these symptoms are observed, it is crucial to assess the ballast and determine whether it needs repair or replacement. In some cases, an unusual buzzing noise may also be a telltale sign of a malfunctioning ballast, indicating that the internal components are struggling to function properly. Prompt attention to these signs can prevent further damage to the lighting system and ensure a safe environment.

To prolong the life of fluorescent tube ballasts, contractors should implement routine maintenance practices. This includes regular inspections of the ballast and wiring, cleaning any dust or debris that may accumulate, and ensuring that the ballast is securely mounted. Furthermore, checking the electrical connections and ensuring that they are tight and free from corrosion can significantly enhance the performance of the ballast. This routine check can also help in identifying potential issues before they escalate, thus saving time and resources.

Additionally, contractors should encourage clients to report any unusual behavior with their lighting systems promptly. Early detection of potential issues can lead to more straightforward solutions and improved customer satisfaction. Educating clients about the importance of maintaining their lighting systems can foster a sense of responsibility and awareness, leading to better care and longevity of their installations. Providing clients with a maintenance schedule or checklist can also empower them to take an active role in the upkeep of their lighting systems, ensuring that they remain functional and efficient for years to come.

In today’s world, energy efficiency and environmental sustainability are more important than ever. Lighting contractors play a vital role in promoting energy-efficient solutions, and selecting the right ballast is a key component of this effort.

Electronic ballasts, in particular, contribute significantly to energy savings. By providing a more stable current and reducing energy waste, these ballasts can lower electricity costs for clients while also minimizing the environmental impact of lighting systems.

Moreover, many electronic ballasts are designed to work seamlessly with high-efficiency fluorescent lamps, further enhancing energy savings. Contractors should educate clients about the benefits of upgrading to more efficient systems, as this can lead to substantial long-term savings.

Proper disposal and recycling of old ballasts are essential for minimizing environmental impact. Many ballasts, especially older magnetic versions, may contain hazardous materials such as PCBs (polychlorinated biphenyls). Contractors should be aware of local regulations regarding ballast disposal and recycling options.

Encouraging clients to recycle old ballasts not only helps protect the environment but also promotes a positive image for the contractor. Providing information on responsible disposal methods can enhance customer relationships and demonstrate a commitment to sustainability.

The lighting industry is constantly evolving, with new technologies and trends emerging regularly. Staying informed about these developments is essential for lighting contractors who wish to remain competitive and provide the best service to their clients.

As technology continues to advance, so does the design and functionality of fluorescent tube ballasts. Innovations such as smart ballasts, which can be integrated into building automation systems, are becoming more prevalent. These ballasts can adjust lighting levels based on occupancy or natural light availability, further enhancing energy efficiency.

Additionally, the development of wireless technology allows for remote monitoring and control of lighting systems, providing contractors with valuable data for maintenance and troubleshooting.

While fluorescent lighting remains popular, the transition to LED technology is gaining momentum. LED lights offer numerous advantages, including longer lifespans, greater energy efficiency, and reduced heat output. As a result, many contractors are beginning to shift their focus toward LED solutions.

However, understanding how to work with existing fluorescent systems, including ballasts, will remain a critical skill. Many LED retrofits require the removal of traditional ballasts, and contractors must be prepared to handle these changes effectively.

Fluorescent tube ballasts are essential tools for lighting contractors, playing a vital role in the performance and efficiency of fluorescent lighting systems. By understanding the different types of ballasts, installation best practices, maintenance, and future trends, contractors can enhance their service offerings and ensure customer satisfaction.

As the industry continues to evolve, staying informed about advancements in ballast technology and the shift toward LED lighting will be crucial for success. By prioritizing energy efficiency and environmental sustainability, lighting contractors can position themselves as leaders in the field, ultimately benefiting both their clients and the planet.

Ready to elevate your lighting projects with the highest quality fluorescent tube ballasts and more? Look no further than LumenWholesale, where we provide lighting contractors with spec-grade products at unbeatable wholesale prices. Say goodbye to local distributor markups and hello to our extensive selection that meets rigorous industry standards. With free shipping on bulk orders, you can stock up on reliable, high-performance lighting without any hidden fees. Make the smart choice for your business and explore our wholesale lighting options at the best value today.

Discover how kitchen modern pendant lights can transform your space with style and efficiency.

Discover how outdoor house lighting fixtures are revolutionizing the work of lighting contractors, enhancing curb appeal, and boosting energy efficiency.

Explore how fancy ceiling fans with integrated lights can boost profitability in lighting installations.

Discover how LED high bay fixtures are revolutionizing lighting contractors’ projects by enhancing efficiency, reducing costs, and improving overall illumination quality.