The junction box cover is a critical component in any electrical installation, particularly in the realm of lighting. For lighting contractors, understanding the nuances of junction box covers—especially the 3 1/2-inch variety—can have significant implications for project efficiency and profitability. This article delves into the importance of these covers, their specifications, and how they can ultimately influence a contractor’s bottom line.

The 3 1/2 junction box cover is designed to fit over a standard junction box, providing protection and ensuring safety in electrical installations. These covers come in various materials, including plastic and metal, each offering distinct advantages and disadvantages. Understanding these materials is essential for contractors aiming to make informed decisions that impact both safety and cost.

Plastic junction box covers are lightweight and resistant to corrosion, making them suitable for indoor applications. They are often less expensive than their metal counterparts, which can be an attractive option for contractors looking to minimize costs. However, plastic covers may not provide the same level of durability and protection against physical impacts. Additionally, plastic can become brittle over time when exposed to UV light, which may limit its effectiveness in certain environments.

On the other hand, metal junction box covers offer superior strength and durability, making them ideal for outdoor or high-impact environments. While they may come at a higher price point, their longevity can justify the initial investment, especially in projects where reliability is paramount. Metal covers also provide better grounding capabilities, which is an important consideration for electrical safety. Furthermore, they can be finished with various coatings to enhance their resistance to rust and corrosion, making them suitable for use in harsh weather conditions.

Installing a 3 1/2 junction box cover requires careful attention to detail. Proper installation ensures that the cover fits securely over the junction box, preventing dust, moisture, and other contaminants from entering. A well-installed cover not only enhances safety but also contributes to the overall aesthetic of the lighting installation. It’s important to check for compatibility between the junction box and the cover, as mismatched sizes can lead to inadequate protection and potential hazards.

Contractors must also consider the tools and time required for installation. Using the right tools can streamline the process, reducing labor costs and minimizing the risk of errors. A thorough understanding of installation best practices can significantly impact a contractor’s efficiency and, ultimately, their profitability. Additionally, contractors should be aware of local building codes and regulations that may dictate specific requirements for junction box covers, ensuring compliance and avoiding costly rework. Training and ongoing education on the latest installation techniques and materials can further enhance a contractor’s skill set, leading to higher quality work and greater client satisfaction.

While the upfront costs of junction box covers may seem minor in the grand scheme of a lighting project, they can have far-reaching financial implications. From material selection to installation practices, every decision made regarding junction box covers can influence a contractor’s bottom line.

Choosing the right material for junction box covers is crucial. While plastic covers may save money initially, their shorter lifespan could lead to increased replacement costs over time. In contrast, investing in metal covers may seem more expensive upfront but can yield savings in the long run due to their durability.

Additionally, bulk purchasing can reduce costs significantly. Contractors who establish relationships with suppliers and negotiate prices for bulk orders can enhance their profit margins. Understanding the total cost of ownership, rather than just the initial purchase price, is essential for making informed decisions. Furthermore, considering the environmental impact of materials can also play a role in financial planning. Sustainable materials may initially cost more but can attract eco-conscious clients and potentially lead to tax incentives or rebates, further offsetting costs.

Labor costs are another critical factor that can be influenced by the choice of junction box cover. A cover that is easy to install can reduce labor time, allowing contractors to complete projects more efficiently. This efficiency can lead to more projects being completed in a shorter time frame, ultimately increasing revenue.

Conversely, a complicated installation process can lead to delays and increased labor costs. Contractors should strive to choose covers that offer a balance between ease of installation and durability, ensuring that they can maintain productivity without sacrificing quality. Moreover, investing in training for staff on the latest installation techniques can also yield dividends. Well-trained workers can tackle installations more swiftly and with fewer errors, which not only cuts down on labor costs but also enhances the overall quality of the work, leading to higher client satisfaction and repeat business.

Adhering to compliance and safety standards is non-negotiable in the electrical contracting industry. Junction box covers must meet specific regulations to ensure the safety of both the installation and the end-users. Understanding these standards is crucial for contractors to avoid costly fines and rework. Moreover, compliance not only safeguards the physical integrity of electrical installations but also fosters a culture of safety that can resonate throughout the entire organization.

Different regions may have varying regulations regarding junction box covers. Contractors must be well-versed in local codes to ensure compliance. Failure to adhere to these regulations can result in penalties, project delays, and reputational damage. For instance, the National Electrical Code (NEC) in the United States outlines specific requirements for junction box installations, including the type of materials that can be used and the necessary ratings for different environments. This knowledge is essential for contractors who operate across multiple jurisdictions, as they must navigate a complex web of local, state, and federal regulations.

Additionally, using compliant materials and covers can enhance a contractor’s credibility. Clients are more likely to trust contractors who prioritize safety and compliance, potentially leading to more business opportunities. Furthermore, demonstrating a commitment to regulatory adherence can serve as a competitive advantage, as many clients are increasingly prioritizing safety and sustainability in their project selections. By staying informed about the latest regulations and best practices, contractors can position themselves as industry leaders.

Insurance premiums and liability considerations are also affected by the choice of junction box covers. Using high-quality, compliant covers can reduce the risk of accidents and damage, which may lead to lower insurance premiums. Conversely, using subpar materials or failing to comply with regulations can increase liability and insurance costs. Insurance companies often conduct audits and assessments to evaluate the safety practices of contractors, and a strong compliance record can result in more favorable terms and conditions.

Contractors should consider the long-term financial implications of their choices. Investing in quality materials and ensuring compliance can lead to significant savings in insurance costs and liability claims over time. Moreover, a proactive approach to safety can minimize the risk of accidents on job sites, which not only protects workers but also enhances overall project efficiency. By fostering a culture of safety and compliance, contractors can create a work environment that prioritizes the well-being of all stakeholders involved, ultimately leading to more successful and sustainable business practices.

customer satisfaction is paramount in the contracting business. Satisfied clients are more likely to refer contractors to others and return for future projects. The choice of junction box covers can play a significant role in achieving high levels of customer satisfaction.

Quality junction box covers not only enhance the safety of electrical installations but also contribute to the overall aesthetics of a project. Clients appreciate attention to detail, and using high-quality materials can reflect positively on a contractor’s workmanship.

Additionally, aesthetically pleasing covers can elevate the perceived value of the installation. Clients who are happy with the appearance of their lighting fixtures and junction boxes are more likely to recommend the contractor to others, leading to increased business opportunities.

Offering after-sales support and warranties for junction box covers can further enhance customer satisfaction. Clients appreciate knowing that they have recourse if issues arise after installation. By providing warranties and being responsive to customer inquiries, contractors can build trust and foster long-term relationships with clients.

Moreover, a solid warranty can differentiate a contractor from competitors. Clients are more likely to choose contractors who stand behind their work and the materials they use, which can lead to increased referrals and repeat business.

To ensure that the choice of junction box covers positively impacts the bottom line, lighting contractors should implement strategies that maximize profitability while maintaining quality and safety.

Building strong relationships with suppliers can lead to better pricing and access to high-quality materials. Contractors should seek out suppliers who offer competitive rates and reliable products. Developing a rapport with suppliers can also lead to favorable terms, such as bulk discounts or flexible payment options.

By leveraging these relationships, contractors can enhance their profit margins and ensure they have access to the best materials for their projects.

Investing in training and education for staff can yield significant returns. Ensuring that all team members are knowledgeable about junction box covers, installation techniques, and compliance standards can lead to improved efficiency and reduced errors.

Additionally, well-trained staff can provide better customer service, enhancing client satisfaction and increasing the likelihood of repeat business. Contractors should consider ongoing training programs to keep their teams updated on industry best practices and new materials.

The choice of a 3 1/2 junction box cover is more than just a technical decision; it is a strategic one that can significantly impact a lighting contractor’s bottom line. By understanding the materials, installation processes, compliance standards, and customer satisfaction factors associated with junction box covers, contractors can make informed decisions that enhance their profitability.

Ultimately, investing in quality materials, building strong supplier relationships, and prioritizing training can lead to increased efficiency, reduced costs, and improved customer satisfaction. In a competitive market, these factors can set contractors apart and contribute to long-term success.

Ready to enhance your lighting projects while boosting your bottom line? Choose LumenWholesale for your junction box cover needs and more. Our spec-grade lighting products are designed to meet the highest industry standards, ensuring reliability and performance for every installation. With unbeatable wholesale prices and the convenience of bulk buying without hidden fees, LumenWholesale is your go-to source for superior lighting solutions. Say goodbye to inflated markups and hello to quality, affordability, and hassle-free shopping with free shipping. Elevate your lighting game and discover the best value in wholesale lighting today!

Discover essential tips for using ceiling fan remote control switches effectively in your lighting projects.

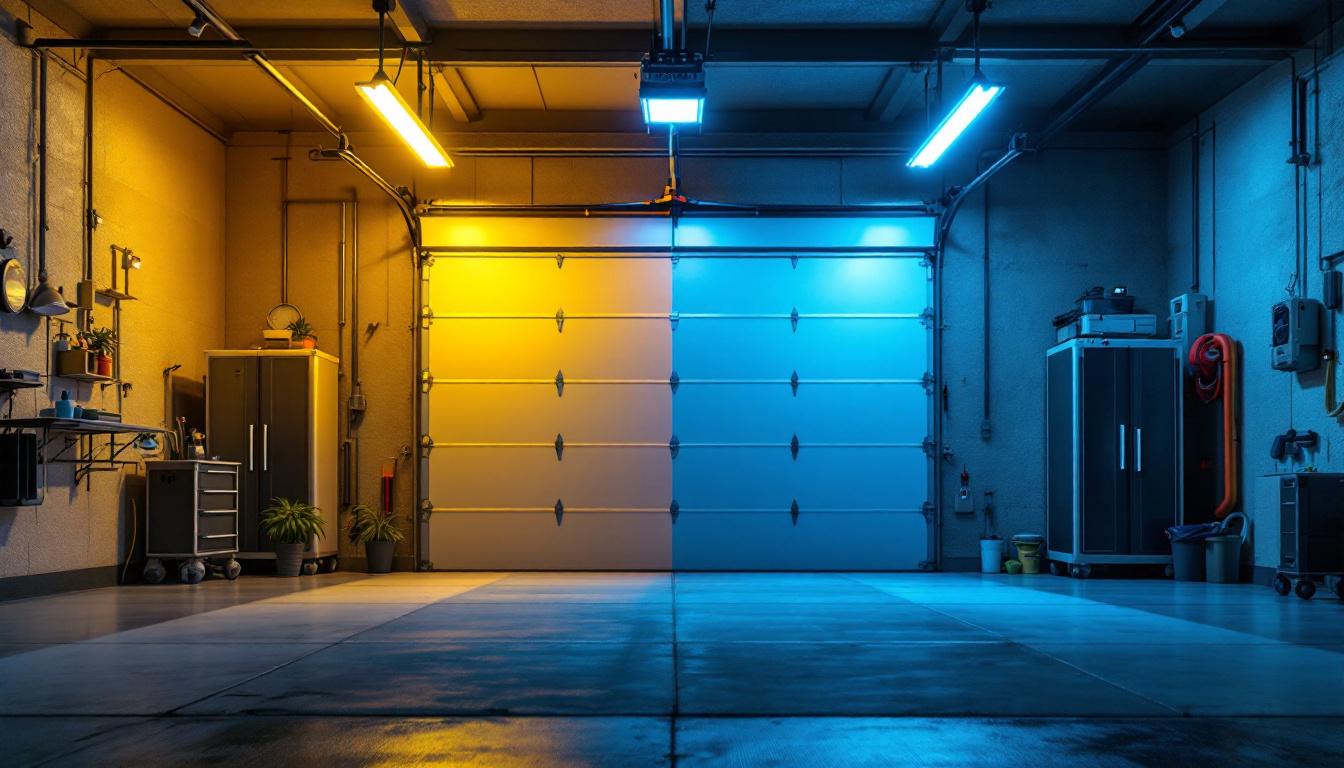

Explore the pros and cons of fluorescent garage lights compared to modern alternatives.

Discover the key factors that distinguish top lighting contractors in the world of LED outdoor house lights.

Discover essential tips for lighting contractors on mastering the 2 recessed square drive installation.