In the ever-evolving world of lighting, fluorescent light ballasts play a crucial role in ensuring optimal performance and efficiency. For lighting contractors, understanding the intricacies of installing these components can significantly enhance service offerings and client satisfaction. This article delves into the importance of fluorescent light ballasts, the installation process, and the benefits they bring to both contractors and end-users.

Fluorescent light ballasts are essential devices that regulate the current to fluorescent lamps. They provide the necessary voltage to start the lamp and then limit the current to ensure stable operation. Without a properly functioning ballast, fluorescent lights can flicker, hum, or fail to start altogether. This regulation is crucial not only for the performance of the light but also for the safety of the electrical system, as an unregulated current can lead to overheating and potential hazards.

In addition to their primary function, ballasts also contribute to energy efficiency. Modern electronic ballasts consume less energy than traditional magnetic ballasts, which can lead to significant cost savings for both contractors and their clients over time. Furthermore, the reduced energy consumption aligns with environmental sustainability goals, as it decreases the overall carbon footprint associated with lighting. As energy regulations become stricter, the adoption of energy-efficient ballasts is increasingly seen as a responsible choice for both residential and commercial applications.

There are primarily two types of fluorescent ballasts: magnetic and electronic. Magnetic ballasts are older technology and tend to be bulkier, while electronic ballasts are more compact and efficient. Understanding the differences between these two types is vital for contractors when selecting the appropriate ballast for a specific application. Magnetic ballasts operate at a lower frequency, which can result in a noticeable flicker in the light output, especially in high-frequency applications. This flicker can be distracting and may even lead to discomfort for those working in environments lit by these older systems.

Electronic ballasts are generally preferred due to their ability to provide a higher frequency output, which results in flicker-free lighting and improved color rendering. Additionally, they are often compatible with dimming systems, offering greater flexibility in lighting design. This compatibility allows users to adjust the brightness according to their needs, enhancing the ambience of a space and contributing to energy savings when full brightness is not required. Moreover, many electronic ballasts are designed with smart technology that can integrate with building management systems, further optimizing energy use and maintenance scheduling.

Upgrading from magnetic to electronic ballasts can yield numerous advantages. First and foremost, electronic ballasts are more energy-efficient, which can lead to lower utility bills for clients. This efficiency also translates to less heat generation, which can prolong the lifespan of both the ballast and the fluorescent lamps. The reduced thermal output is particularly beneficial in settings where temperature control is critical, such as in museums or laboratories, where excessive heat can damage sensitive materials or equipment.

Moreover, electronic ballasts often come equipped with features such as rapid start and instant on capabilities, enhancing the overall user experience. These features not only improve convenience but also ensure that spaces are adequately lit without delay, which is especially important in commercial environments where time is of the essence. For contractors, recommending these upgrades can position them as knowledgeable professionals who prioritize energy efficiency and customer satisfaction. Additionally, the transition to electronic ballasts can open up opportunities for contractors to offer maintenance services, as these systems often require less frequent replacements and repairs, thus establishing long-term relationships with clients based on reliability and trust.

Installing a fluorescent light ballast may seem straightforward, but it requires careful attention to detail and adherence to safety protocols. Proper installation not only ensures optimal performance but also minimizes the risk of future failures. A well-installed ballast can significantly extend the lifespan of fluorescent lamps and improve energy efficiency, making it a worthwhile investment for both residential and commercial settings.

Before starting the installation, it is essential to gather all necessary tools and materials. Common tools include a screwdriver, wire cutters, wire strippers, and a voltage tester. Additionally, having the correct replacement ballast on hand is crucial, as compatibility with the existing fixtures is paramount. It’s also wise to have a flashlight handy, especially if you are working in a dimly lit area or a cramped space where visibility may be compromised.

Contractors should also ensure they have safety equipment, such as gloves and goggles, to protect themselves during the installation process. Taking these precautions can prevent accidents and ensure a smooth workflow. Furthermore, it is advisable to have a first aid kit nearby, as electrical work can sometimes lead to unexpected injuries. Being prepared for any situation can make the installation process safer and more efficient.

The installation of a fluorescent light ballast can be broken down into several key steps:

While the installation process is generally straightforward, contractors may encounter several challenges. One common issue is identifying the correct ballast type for the existing fixture. This can often be resolved by consulting the fixture’s specifications or the manufacturer’s guidelines. Additionally, understanding the different types of ballasts—such as magnetic versus electronic—can further aid in selecting the right component for the job.

Another challenge may arise from outdated wiring or fixtures that do not comply with current electrical codes. In such cases, it may be necessary to update the wiring or consult a licensed electrician to ensure safety and compliance. It’s also important to consider the age of the fluorescent fixtures themselves; older models may require more extensive upgrades to accommodate modern ballasts, which can lead to additional work but ultimately enhance the lighting quality and energy efficiency of the space.

To maximize efficiency and customer satisfaction, lighting contractors should adopt several best practices when installing fluorescent light ballasts. These practices not only enhance the quality of work but also build trust with clients.

Before starting any installation, conducting a thorough site assessment is essential. This includes evaluating the existing lighting setup, identifying potential issues, and discussing the client’s needs and preferences. By taking the time to understand the client’s requirements, contractors can recommend the most suitable ballast options and lighting solutions.

Additionally, assessing the overall electrical system can help identify any underlying issues that may affect the performance of the new ballast. Addressing these concerns upfront can prevent future complications and ensure a successful installation.

Contractors should take the opportunity to educate clients about the benefits of upgrading to modern ballasts. Providing information on energy savings, improved lighting quality, and longer lamp life can help clients make informed decisions.

Furthermore, discussing maintenance tips and the importance of regular inspections can foster a sense of partnership between the contractor and the client. This proactive approach can lead to repeat business and referrals, ultimately benefiting the contractor’s reputation and bottom line.

As technology continues to advance, the future of fluorescent lighting is evolving. While LED lighting is gaining popularity due to its energy efficiency and longevity, fluorescent lights still hold a significant place in various applications.

For lighting contractors, staying informed about industry trends and emerging technologies is crucial. Understanding the advantages and limitations of different lighting options allows contractors to provide the best solutions for their clients.

One of the most exciting developments in the lighting industry is the integration of smart technology. Many modern ballasts and fixtures now offer compatibility with smart home systems, allowing for enhanced control over lighting environments.

Contractors who embrace these advancements can offer clients innovative solutions that enhance convenience and energy efficiency. This integration not only appeals to tech-savvy consumers but also positions contractors as forward-thinking professionals in a competitive market.

Installing fluorescent light ballasts is a vital skill for lighting contractors, offering numerous benefits that can enhance service offerings and client satisfaction. By understanding the role of ballasts, mastering the installation process, and adopting best practices, contractors can position themselves as experts in the field.

As the lighting industry continues to evolve, staying informed about emerging technologies and trends will be essential for long-term success. Embracing innovation while maintaining a commitment to quality and customer service will ensure that lighting contractors remain competitive and relevant in an ever-changing market.

Ready to elevate your lighting installations with the best-in-class fluorescent light ballasts and more? Look no further than LumenWholesale, where we provide lighting contractors with the highest quality, spec-grade lighting products at unbeatable wholesale prices. Say goodbye to middleman markups and hello to a vast selection of reliable, high-performance lighting essentials that meet the strictest industry standards. With the added benefits of free shipping and bulk buying made easy, you can ensure your projects shine bright while keeping costs low. Don’t compromise on quality or value; visit LumenWholesale now for wholesale lighting at the best value.

Discover expert insights and best practices for integrating floodlights with outlets in your projects.

Discover why the gooseneck sign light fixture is an essential element for any successful lighting project.

Discover the transformative benefits of modern ceiling lamps for lighting contractors.

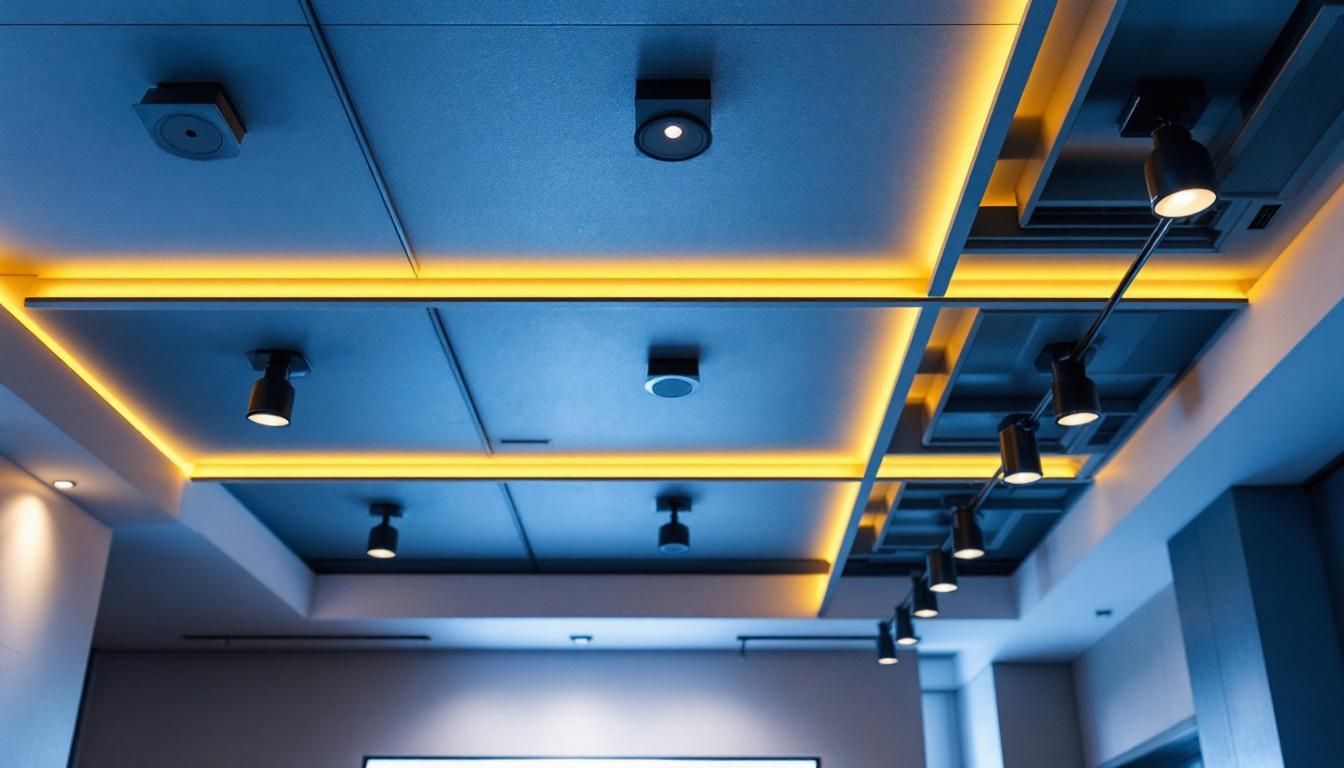

Explore the transformation of dropped ceiling lights in the lighting industry, highlighting innovative designs, energy efficiency, and their impact on modern interiors.