In the realm of commercial and industrial lighting, safety is paramount. One area that often requires special attention is freezer lighting. The harsh conditions of cold storage environments present unique challenges, making the choice of lighting crucial for both safety and efficiency. LED freezer lights have emerged as a preferred solution, not only for their energy efficiency but also for their ability to enhance safety in various lighting installations.

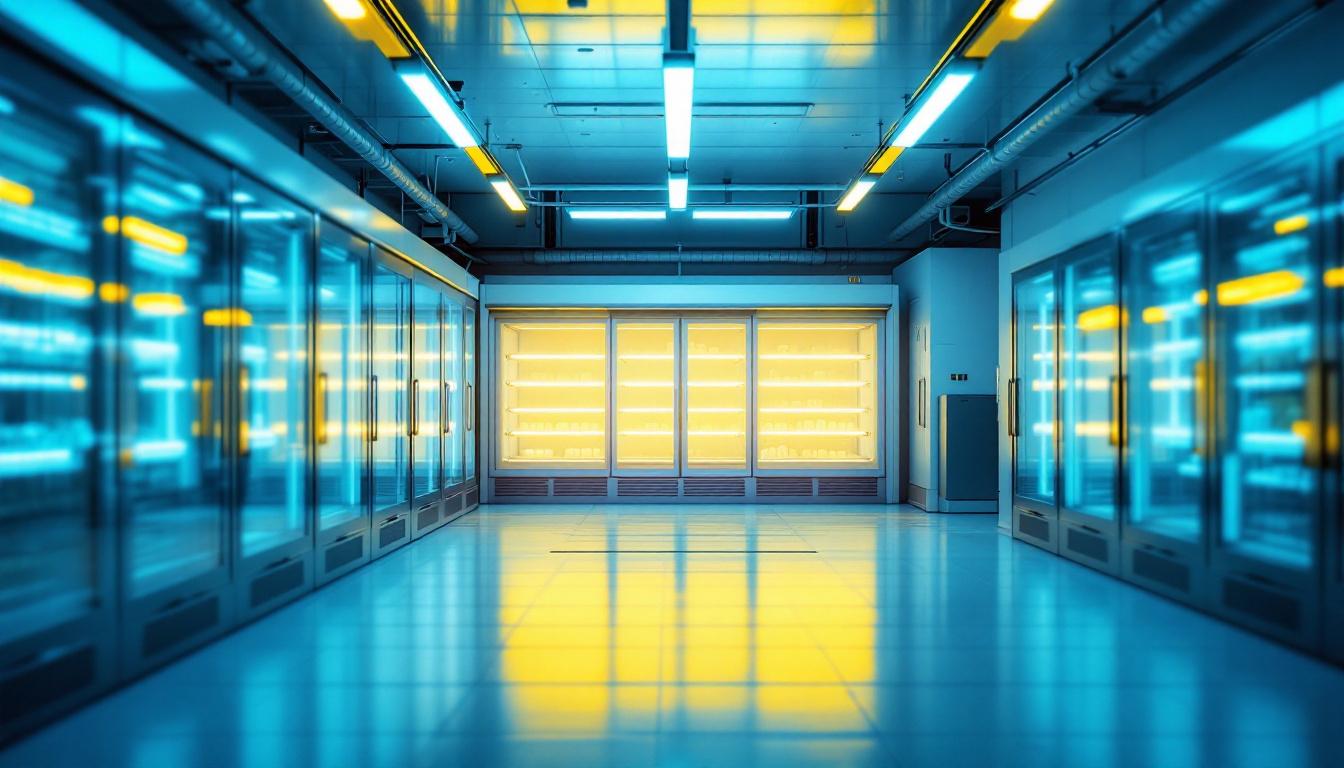

Freezer environments, such as those found in supermarkets, warehouses, and food processing plants, operate under specific conditions that can complicate lighting choices. The low temperatures, high humidity, and the need for consistent visibility require specialized lighting solutions. Proper lighting not only enhances visibility for staff but also plays a crucial role in maintaining product quality and safety, as inadequate lighting can lead to mistakes in inventory management and product handling.

Traditional lighting options, such as incandescent or fluorescent bulbs, often struggle in freezer environments. These types of lights can flicker, dim, or even fail entirely when exposed to extreme cold. Furthermore, the frequent cycling of these lights can lead to increased maintenance costs and potential safety hazards due to inadequate visibility. The flickering and dimming can also create an uncomfortable working environment, potentially affecting employee productivity and morale.

Moreover, traditional bulbs are less energy-efficient, resulting in higher operational costs. This inefficiency can be particularly detrimental in commercial settings where lighting is on for extended periods. The need for a reliable, energy-efficient solution is evident, and this is where LED technology shines. Additionally, the heat generated by traditional bulbs can contribute to temperature fluctuations within the freezer, which may compromise the integrity of stored products. Maintaining a stable temperature is essential for preserving the quality of perishable goods, making the choice of lighting even more critical.

LED freezer lights are designed specifically to withstand the rigors of cold environments. They offer several advantages over traditional lighting options, making them an ideal choice for safety-focused installations. One of the most significant benefits is their durability. LED lights are solid-state devices, meaning they are less prone to breakage compared to fragile glass bulbs. This resilience is crucial in environments where equipment may be moved frequently or where accidental impacts can occur.

In addition to their durability, LED lights also provide superior energy efficiency, consuming significantly less power than their incandescent and fluorescent counterparts. This efficiency translates into lower electricity bills and a reduced carbon footprint, aligning with the growing emphasis on sustainability in the food industry. Furthermore, LEDs have a longer lifespan, often lasting up to 25 times longer than traditional bulbs, which not only minimizes replacement frequency but also reduces waste. The ability to produce bright, consistent light without the flickering or warm-up time associated with older technologies ensures that staff can work safely and efficiently, even in the coldest conditions.

Safety is a critical concern in any lighting installation, but it becomes even more pronounced in freezer environments. Poor visibility can lead to accidents, injuries, and costly damage to products and equipment. LED freezer lights enhance safety in several key ways.

LED lights provide superior brightness and clarity compared to traditional lighting options. The high lumen output ensures that every corner of the freezer is well-lit, reducing the risk of accidents caused by poor visibility. This is particularly important in areas where employees are handling heavy equipment or navigating narrow aisles.

Furthermore, LED lights have a more focused beam angle, allowing for better light distribution. This focused illumination minimizes shadows and dark spots, creating a safer working environment. Employees can quickly identify hazards, locate products, and move about with confidence. In addition, the color temperature of LED lights can be tailored to enhance visibility; cooler light temperatures can make it easier to distinguish between different products, which is especially useful in large freezers stocked with various items.

Another safety feature of LED freezer lights is their instant-on capability. Unlike fluorescent bulbs, which can take time to warm up and reach full brightness, LEDs illuminate immediately. This instant illumination is crucial in emergency situations or during power outages, where every second counts.

Additionally, LED lights operate flicker-free, reducing eye strain and fatigue among workers. Continuous flickering can lead to headaches and decreased productivity, which can indirectly affect safety. By eliminating these issues, LED freezer lights contribute to a healthier and safer work environment. Moreover, the durability of LED technology means they are less likely to break or shatter, further reducing the risk of injury from broken glass or electrical hazards. This resilience is particularly important in freezer settings where temperatures can be extreme, ensuring that the lighting remains operational and safe over time.

Energy efficiency is a significant consideration for any lighting installation, especially in commercial settings where operational costs can quickly add up. LED freezer lights not only enhance safety but also offer substantial energy savings.

LED lights consume significantly less energy than traditional lighting options. This reduced energy consumption translates into lower electricity bills, allowing businesses to allocate resources more effectively. In environments where lighting is required 24/7, these savings can be substantial over time.

Moreover, many utility companies offer incentives for businesses that switch to energy-efficient lighting solutions. These incentives can further offset the initial investment in LED technology, making it a financially sound choice for lighting contractors and facility managers.

Another factor contributing to the cost-effectiveness of LED freezer lights is their long lifespan. LEDs can last up to 50,000 hours or more, significantly outlasting traditional bulbs. This longevity means fewer replacements and less frequent maintenance, resulting in reduced labor costs and downtime.

In high-demand environments like freezers, where maintenance can be disruptive, the extended lifespan of LED lights is a considerable advantage. Fewer replacements also mean less waste, aligning with sustainability goals that many organizations strive to achieve.

While the benefits of LED freezer lights are clear, proper installation is crucial to fully realize their advantages. Lighting contractors must consider several factors to ensure optimal performance and safety.

Not all LED lights are created equal, especially when it comes to freezer applications. It is essential to select fixtures specifically designed for cold environments. These fixtures should be rated for low temperatures and have appropriate IP ratings to withstand humidity and condensation.

Additionally, the choice of color temperature can impact visibility. Cooler color temperatures (around 5000K) are often preferred in freezer environments as they provide a bright, daylight-like illumination that enhances visibility and reduces the perception of cold.

The placement of LED freezer lights is critical for achieving even illumination and minimizing shadows. Lighting contractors should conduct a thorough assessment of the space to determine the optimal layout. This may involve using lighting design software to simulate light distribution and identify potential problem areas.

Strategically placing lights to avoid dark spots and ensure adequate coverage in high-traffic areas can significantly enhance safety. Additionally, incorporating motion sensors or dimmers can further improve energy efficiency and adaptability to changing conditions.

In any lighting installation, compliance with safety standards and regulations is essential. This is particularly true in commercial settings where safety is a top priority. LED freezer lights must meet specific standards to ensure they are safe for use in cold environments.

Different regions and industries may have varying regulations regarding lighting installations. It is crucial for lighting contractors to stay informed about these requirements, including those related to energy efficiency, safety, and environmental impact.

For instance, the National Electrical Code (NEC) provides guidelines for electrical installations, including those in freezer environments. Ensuring compliance with these codes not only enhances safety but also protects businesses from potential legal liabilities.

Even with the durability of LED lights, regular maintenance and inspections are essential to ensure ongoing safety and performance. Lighting contractors should establish a maintenance schedule that includes checking fixtures, cleaning lenses, and replacing any damaged components.

Routine inspections can help identify potential issues before they become significant problems, ensuring that the lighting remains effective and safe for all users. This proactive approach can also extend the lifespan of the lighting system, maximizing the initial investment.

As the demand for energy-efficient and safe lighting solutions continues to grow, LED freezer lights are poised to become the standard in cold storage environments. Their numerous benefits, including enhanced safety, energy efficiency, and reduced maintenance costs, make them an ideal choice for lighting contractors and facility managers alike.

By understanding the unique challenges of freezer environments and leveraging the advantages of LED technology, businesses can create safer, more efficient workplaces. As the industry evolves, the integration of advanced lighting solutions will play a crucial role in enhancing safety and operational efficiency in all types of installations.

In conclusion, investing in LED freezer lights is not just a smart financial decision; it is also a commitment to safety and sustainability in lighting installations. As technology continues to advance, the possibilities for improving safety and efficiency in freezer environments will only expand, paving the way for a brighter, safer future.

Ready to elevate your lighting installations to new heights of safety and efficiency? Look no further than LumenWholesale for all your LED freezer light needs. Our commitment to providing contractors with the highest quality, spec-grade lighting products at unbeatable wholesale prices ensures that your projects shine without breaking the bank. Say goodbye to inflated markups and hello to hassle-free bulk buying with free shipping. Don’t compromise on quality or value; choose LumenWholesale for premium lighting solutions that meet the toughest industry standards. Wholesale Lighting at the Best Value is just a click away—transform your lighting installations today!

Discover the ultimate guide to LED replacement can lights, covering everything from installation tips to energy-saving benefits.

Discover how occupancy/vacancy sensor switches can enhance lighting efficiency for contractors.

Discover the ultimate guide to the best under cabinet lighting solutions that enhance your home’s ambiance while maximizing energy efficiency.

Discover the top challenges faced by lighting contractors with LED wall sconce lights.